A water pump controller is a device used to manage the operation of water pumps in various systems. Its main function is to automate the pumping process, ensuring water is delivered efficiently to required areas while minimizing wastage, preventing overflows, and protecting the pump from potential damage. These controllers are integral to residential, agricultural, commercial, and industrial water management systems.

In this article, we will explore the three basic types of water pump controllers and the mechanisms behind how they work.

What Are the Three Basic Types of Controllers?

Water pump control boxes can generally be classified into three categories: manual controllers, automatic controllers, and programmable controllers. Each type has unique features and applications suited to different operational needs.

1. Manual Controllers

Manual controllers are the simplest form of water pump controllers. They require direct human intervention to start or stop the pump.

How They Work?

· Users must monitor the water levels, pressure, or flow manually and operate the pump accordingly.

· For example, in a water tank, the user will turn on the pump when the tank is low and turn it off when it is full.

Applications

· Manual controllers are commonly used in small-scale or low-tech settings where automated solutions are unnecessary or not feasible.

· Examples include rural households, small agricultural setups, or temporary water systems.

Advantages

· Simple design and operation

· Low initial cost

· Minimal technical requirements

Disadvantages

· Labor-intensive, as it relies on constant human monitoring

· Higher risk of human error, leading to potential issues such as overflows or dry running of the pump

· Inefficient for large-scale or continuous operations

2. Automatic Controllers

Automatic controllers are more advanced than manual ones, as they use sensors and relays to automate pump operation. These systems monitor water levels, pressure, or flow in real time and operate the pump without requiring human intervention.

How They Work?

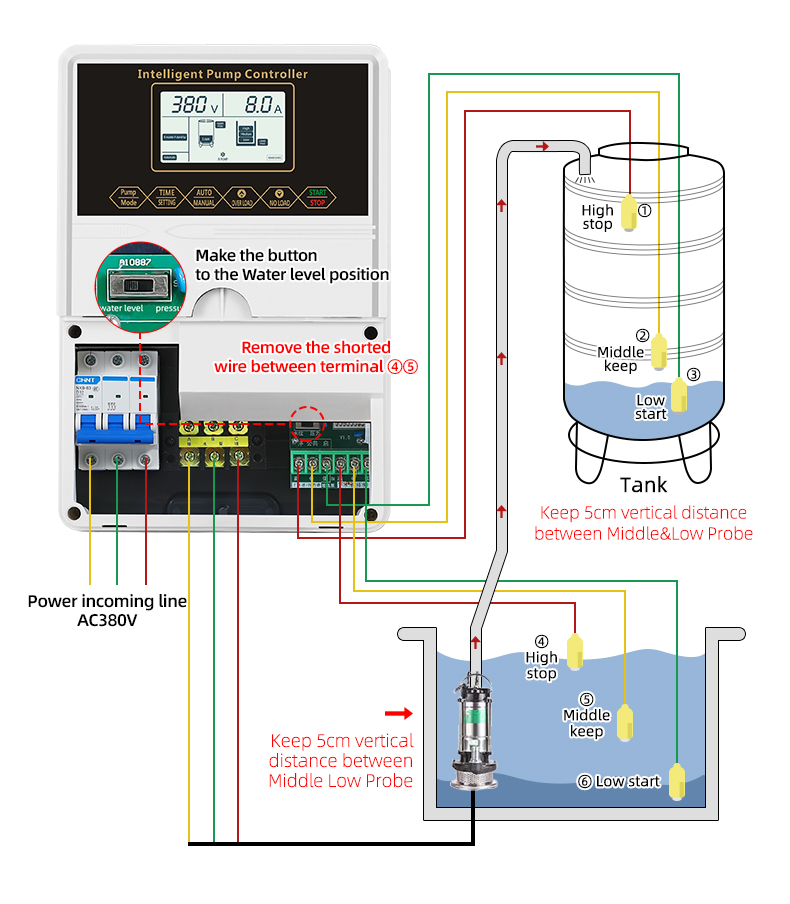

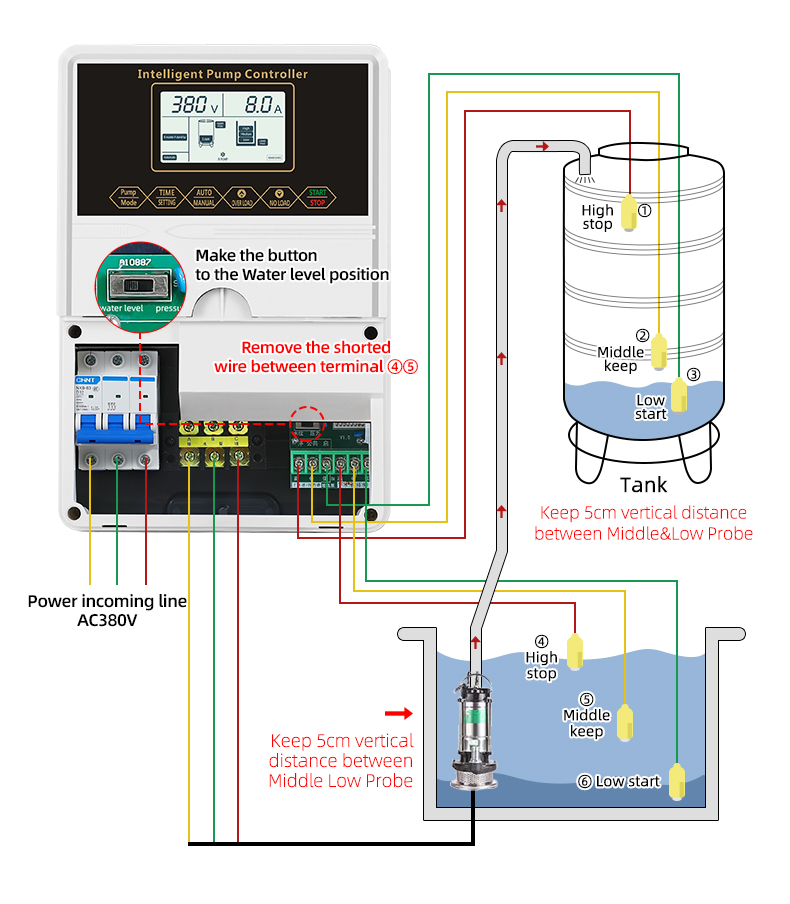

· Sensors (e.g., float switches, pressure switches, flow sensors) monitor specific parameters like water level or pressure.

· Based on the sensor readings, the controller activates or deactivates the pump. For instance:

A float switch in a water tank can detect when water falls below a certain level, triggering the pump to fill the tank.

A pressure switch can detect a drop in water pressure and activate the pump to restore normal levels.

Applications

· Automatic controllers are widely used in residential water systems, irrigation, and industrial processes.

· They are ideal for systems where water levels or demand fluctuate frequently.

Advantages

· Reduces the need for manual monitoring

· Enhances system efficiency and reliability

· Prevents common issues like pump dry running or overflow

Disadvantages

· Higher initial cost compared to manual systems

· Requires regular maintenance and calibration to ensure accuracy

3. Programmable Controllers

Programmable controllers are the most advanced type of water pump controllers. They allow users to customize the operation of the pump according to specific needs, offering the highest level of precision and flexibility.

How They Work?

· These controllers use microprocessors or programmable logic controllers (PLCs) to manage pump operations based on user-defined settings or algorithms.

· Features may include:

Timers for scheduled operation

Variable frequency drives (VFDs) to adjust motor speed based on demand

Remote monitoring and control through smart home or industrial IoT systems

Applications

· Programmable controllers are ideal for complex systems such as municipal water supply networks, large-scale irrigation systems, and industrial processes requiring precise control.

Advantages

· High efficiency and adaptability

· Remote control and monitoring capabilities

· Can manage complex systems with multiple inputs and outputs

Disadvantages

· Expensive to install and maintain

· Requires technical expertise for programming and troubleshooting

How Does a Water Pump Controller Work?

The operation of a water well pump controller involves several key steps: input detection, signal processing, output control, and safety mechanisms. While the specifics depend on the type of controller, the underlying principles are generally consistent.

1. Input Detection

The controller continuously receives data from sensors that monitor key parameters, such as:

· Water level: Measured using float switches, ultrasonic sensors, or capacitive level sensors.

· Pressure: Monitored using pressure switches or transducers.

· Flow: Detected using flow meters or other flow-monitoring devices.

Example

In a residential water tank system, a float switch detects when the water level drops below a pre-defined threshold and sends a signal to the controller.

2. Signal Processing

The controller processes the input signals to determine whether the pump needs to be activated or deactivated. This decision is based on preset parameters or programmable logic.

· Automatic Controllers: Use simple logic to turn the pump on or off based on sensor thresholds.

· Programmable Controllers: Utilize advanced algorithms and may factor in multiple inputs, historical data, or user-defined schedules.

Example

In an agricultural irrigation system, the controller may use soil moisture sensors and weather data to decide when and how long to operate the pump.

3. Output Control

Once the controller decides on an action, it sends an output signal to the pump via relays or motor drivers. This signal activates or deactivates the pump motor.

· Relay System: Opens or closes the electrical circuit to control the pump.

· Variable Frequency Drives (VFDs): Adjust the motor speed to match demand, saving energy and reducing wear.

Example

In a high-rise building, the controller adjusts pump operation to maintain consistent water pressure across all floors.

4. Safety Mechanisms

Modern controllers include safety features to protect the pump and ensure system reliability. Common features include:

· Dry-run protection: Stops the pump if no water is detected in the source, preventing overheating.

· Overload protection: Shuts off the pump if excessive current is detected, protecting the motor.

· Leak detection: Identifies abnormal flow patterns indicating potential leaks.

Example

In a drainage system, the controller shuts off the pump if water flow exceeds normal levels, indicating a leak or pipe burst.

Real-World Applications of Water Pump Controllers

Water well pump control boxes are essential across various domains, ensuring efficient and reliable water management.

1. Residential Applications

· Automating water supply from underground tanks to overhead tanks

· Preventing overflow and dry running in household water systems

· Integration with smart home systems for remote monitoring and control

2. Agricultural Applications

· Efficient irrigation through automatic or programmable controllers

· Drip irrigation systems with precise water delivery

· Remote management of pumps in large fields

3. Industrial Applications

· Managing cooling systems in factories

· Controlling water flow in manufacturing processes

· Sewage and wastewater management systems

4. Municipal Water Supply

· Regulating water distribution in urban areas

· Maintaining consistent pressure in multi-level buildings

· Managing large-scale pumping stations for water treatment plants

Conclusion

Water pump controllers are indispensable for modern water management systems. They streamline pump operations, reduce manual intervention, and protect pumps from damage, ensuring efficient and reliable water delivery. From simple manual systems to sophisticated programmable controllers, each type serves specific needs and applications.

Choosing the right water pump controller depends on factors like the system's complexity, budget, and operational requirements. Whether for a residential water tank, agricultural irrigation system, or industrial process, a well-designed controller can significantly enhance efficiency and sustainability.