Managing industrial wastewater isn't just about compliance—it’s about operational efficiency, equipment longevity, and resource control. Whether it's from manufacturing, chemical processing, food production, or mining, industrial wastewater must be handled with care. The volume, flow rate, and potential for solids or chemicals make it a challenge to pump and discharge safely and efficiently.

In many facilities, wastewater pumps are still operated with basic on/off switches, manual timing, or fixed-speed controls, which may lead to overflows, dry runs, excessive energy use, or premature equipment wear. These problems often go unnoticed—until they result in costly downtime or violations.

That's why more operations are turning to smart automation. An automatic water pump controller system takes the guesswork out of wastewater management and delivers smarter, safer, and more sustainable control.

This article explores the three critical benefits of using an automatic water pump controller system in industrial wastewater applications—and why it's fast becoming a best practice across industries.

Table of Contents

Reliable, Real-Time Control to Prevent Overflow and Equipment Damage

Improved Energy Efficiency and Smarter Pump Operation

Remote Monitoring, Early Fault Detection, and Operational Visibility

Why an Automatic Water Pump Controller System Is a Smart Investment for Industrial Wastewater

Why Choose JNN Automatic Water Pump Controllers?

1. Reliable, Real-Time Control to Prevent Overflow and Equipment Damage

In industrial wastewater environments, inflow is rarely steady. It may spike during cleaning shifts, fluctuate with production cycles, or drop to minimal levels overnight. Fixed-timer systems or manual switching simply can't keep up with this variability.

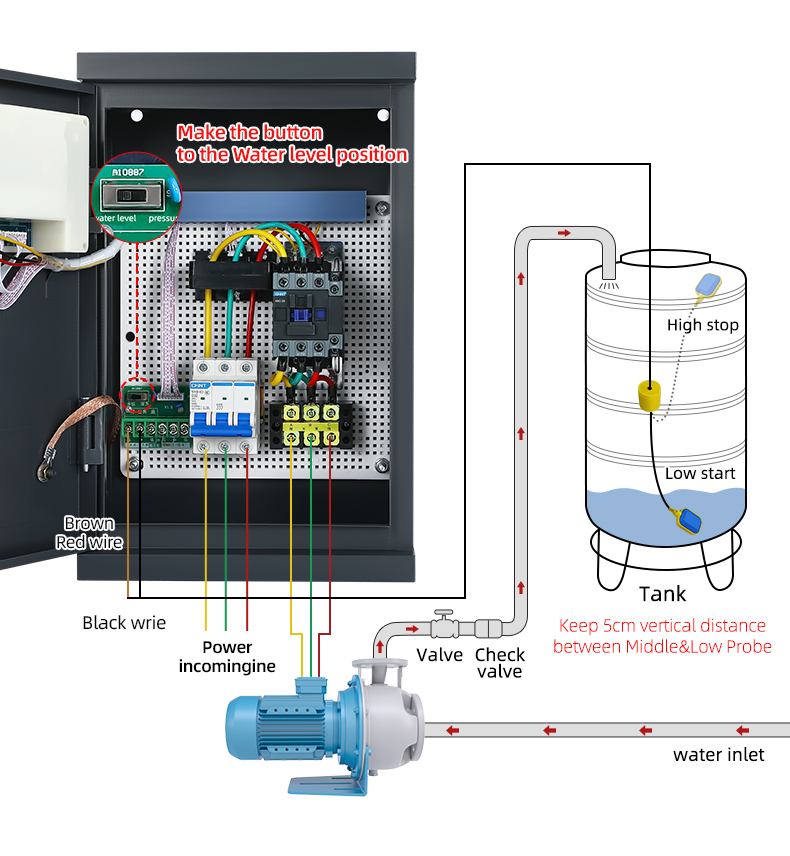

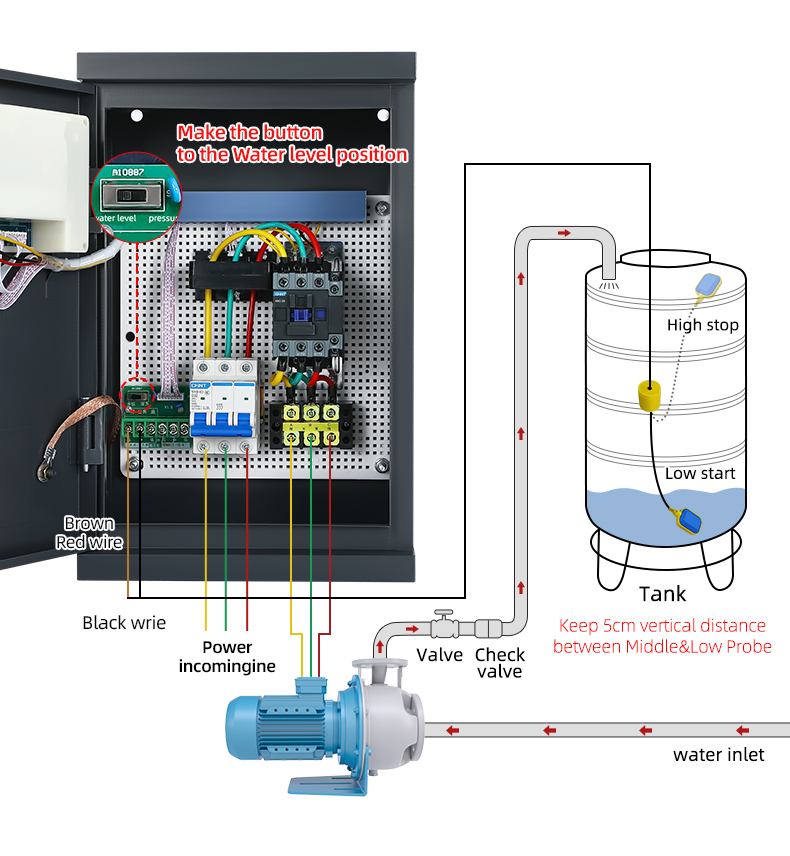

An automatic water pump controller solves this by responding in real time to actual water levels and system conditions. It monitors multiple parameters simultaneously and takes intelligent action without delay.

Further expanded function description:

In processes with heavy solids or chemical residues, inconsistent flow can cause pumps to run dry or cavitate, leading to expensive motor or impeller failure. The controller stops the pump within seconds when water levels dip too low.

During batch discharges, the system automatically detects the inflow spike and initiates a pump cycle before an overflow occurs—no need for an operator to be present.

In treatment pits with variable inflow and delayed gravity drainage, the controller uses dual-sensor logic to prevent backflow or siphoning during pump rest periods.

This smart adaptability doesn't just protect the pump—it helps maintain stable back-end operations such as pre-treatment tanks, filter presses, or neutralization chambers, reducing system-wide risk.

By maintaining precise control, the system reduces emergency maintenance, ensures smoother downstream treatment, and helps keep your plant compliant without constant staff supervision.

2. Improved Energy Efficiency and Smarter Pump Operation

Wastewater pumping systems are often"set and forget"—but this usually means running pumps harder and longer than necessary. In facilities where discharge is intermittent, or where wastewater is pumped across long distances or uphill, the energy wasted in overpumping can be significant.

An automatic water pump control box enables true demand-based efficiency by synchronizing pump output with actual load.

More in-depth energy-saving control methods:

For systems with multi-stage pumping, the controller can manage startup sequences to avoid peak demand charges from the utility company.

With VFDs, the controller regulates RPM in response to real-time pipe friction loss, optimizing not only for energy but also for pump life.

During standby or low-production hours, the system enters sleep mode and “wakes up” instantly when triggered by sensor thresholds—keeping standby power draw close to zero.

In plants that operate 24/7 but with variable output—like bottling lines or food prep facilities—automatic controllers ensure water is moved only when it needs to be, and at the exact rate required.

Facility teams often report reduced wear on motors, quieter system operation, and fewer night-shift troubleshooting calls. Over a year, these efficiencies can cut thousands off power bills, particularly in sites with multiple pump stations.

3. Remote Monitoring, Early Fault Detection, and Operational Visibility

Manual pump checks are not only time-consuming—they're reactive. By the time a technician notices a flow issue or hears a strange vibration, the problem may already be causing damage.

With an automatic water well pump controller, industrial wastewater systems become proactively managed. Operators don’t just see what's happening—they're alerted when things begin to drift out of range.

Extended visualization and intelligent linkage functions:

A remote dashboard displays trends in run time, flow rate, and energy use, making it easier to compare sites, shifts, or daily demand patterns.

The system supports predictive logic: if a pump's startup time increases or current draw spikes over time, it flags potential issues before failure occurs.

Controllers can be programmed to interact with tank level controllers, pressure boosters, or even PLC-based treatment systems for coordinated operation.

This level of transparency is a game-changer in decentralized operations, such as industrial parks, chemical plants, or multi-facility networks. One centralized maintenance team can monitor multiple pump stations without leaving their control room.

When something goes wrong—say a rising trend in amperage suggests bearing wear—the system can send an alert early, avoiding unplanned downtime and saving the cost of an emergency service call.

Why an Automatic Water Pump Controller System Is a Smart Investment for Industrial Wastewater

Pumping wastewater isn't just a mechanical task—it's a vital function with real consequences. From preventing chemical spills to avoiding flooded basements or overflow tanks, the way your pumps are controlled makes a measurable impact.

An automatic water pump controller system offers a way to:

Run smarter, not harder

See deeper into your system's behavior

Act faster, with fewer surprises

Protect equipment, staff, and regulatory compliance

Whether you operate in food processing, metal finishing, pharmaceuticals, or any industry producing complex effluents, intelligent pump control is no longer optional—it's a cost-effective necessity.

Why Choose JNN Automatic Water Pump Controllers?

At JNN, we understand that industrial wastewater is dynamic, unpredictable, and critical. That's why we build automatic water pump controllers that deliver:

✅ Smart control logic tailored for wastewater challenges

✅ Seamless integration with VFDs and industrial sensors

✅ Built-in safety protection with instant response

✅ Remote access for full system visibility and real-time alerts

With JNN, you're not just installing a controller—you're building a smarter, safer, and more efficient wastewater system from the inside out.

Explore our industrial-grade automatic water pump controller solutions today—and bring reliability and intelligence to every drop of your wastewater management.