Construction sites are constantly evolving, and water management is one of the most overlooked, yet essential, aspects of keeping things running smoothly. Whether it's groundwater removal, concrete curing, or general site dewatering, pumps play a central role in keeping timelines on track and hazards under control.

But managing those pumps manually often leads to inefficiencies, unexpected equipment strain, and rising operational costs. Without automation, crews must monitor water levels by hand, start and stop pumps manually, and risk system failures when conditions change faster than people can react.

That's where an automatic water pump controller makes a significant impact. By introducing automation, precision, and responsiveness into your pumping system, these controllers take the guesswork out of water management—freeing up time, reducing cost, and protecting valuable equipment.

In this article, we'll explore three practical ways an automatic water pump controller can improve efficiency on construction sites—based on real challenges, not theory.

Table of Contents

How Does an Automatic Water Pump Controller Improve On-Site Response and Labor Efficiency?

Can Smart Pump Control Really Save Energy and Reduce Costs on Construction Sites?

How Does Pump Automation Help Prevent Equipment Failure and Downtime?

Is It Time to Upgrade Your Construction Site's Pumping System?

Why Choose JNN Automatic Water Pump Controllers?

How Does an Automatic Water Pump Controller Improve On-Site Response and Labor Efficiency?

On construction sites, time and manpower are two of the most valuable resources—and managing water flow manually often puts unnecessary pressure on both. Whether it’s groundwater accumulation in excavations, water delivery for curing concrete, or runoff control during rainfall, traditional pump operation usually requires someone physically present to monitor levels, start or stop the pump, and adjust its performance.

That might work on smaller projects, but for larger or more complex sites, this method quickly becomes inefficient—and even risky.

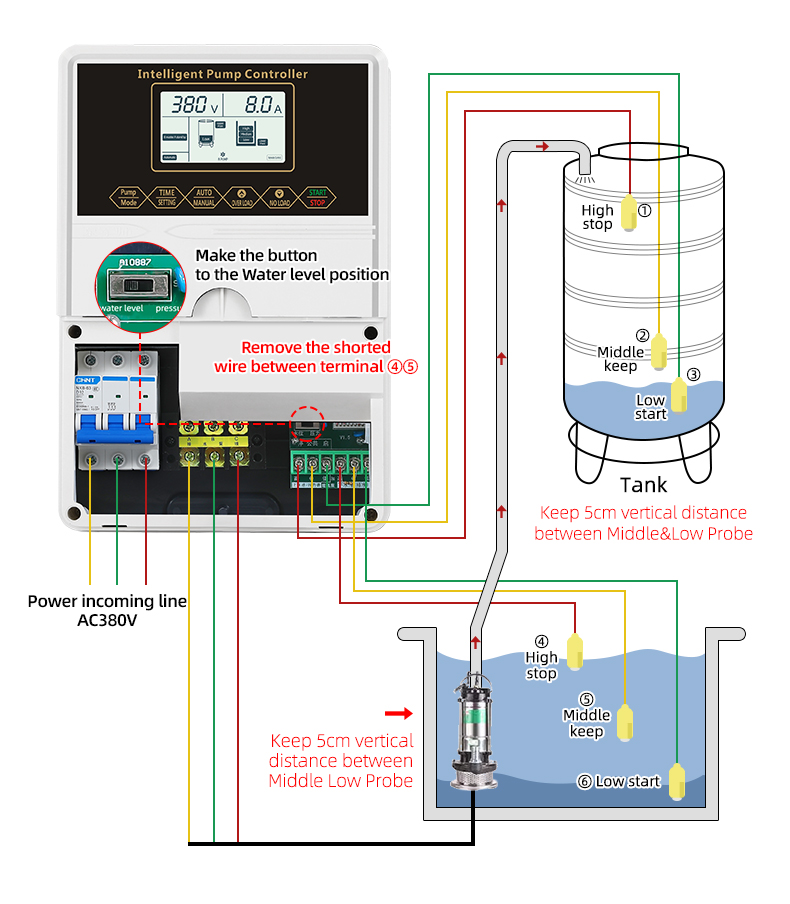

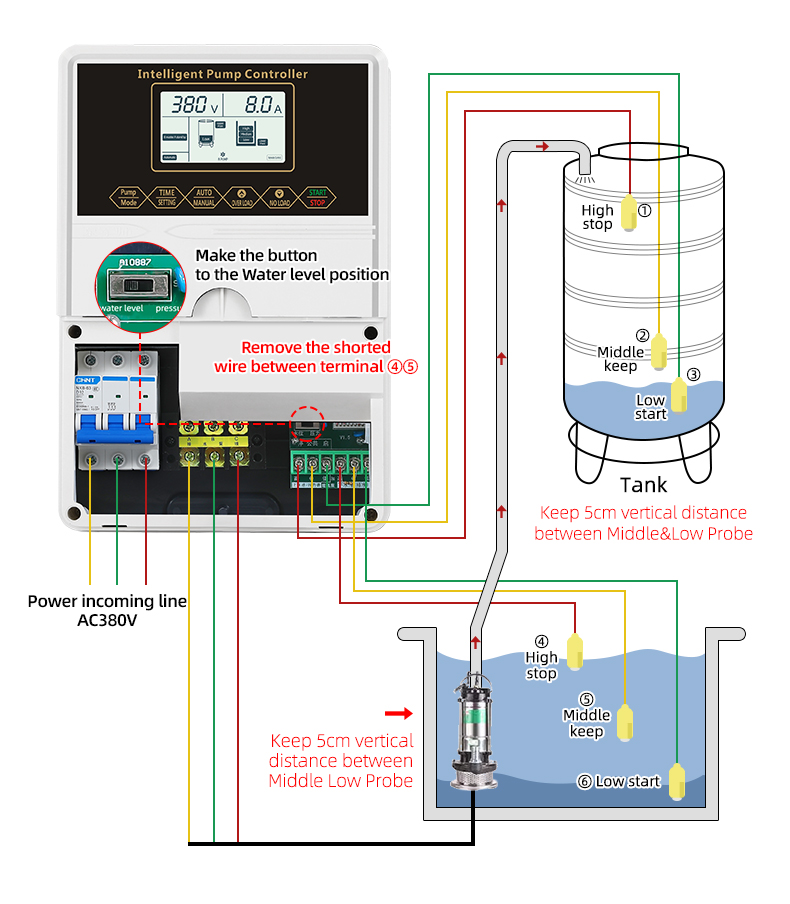

An automatic water pump control box helps solve this by automating all those repetitive tasks. Instead of relying on manual timing or visual checks, the system continuously receives data from sensors placed in pits, tanks, or water collection zones. It can detect when water levels rise beyond a certain point and immediately start the pump, or shut it down precisely when levels drop—without human intervention.

This real-time responsiveness can make a measurable difference during tasks like:

Dewatering during foundation or basement excavation

Handling sudden rainwater inflow in trench work

Controlling flow in temporary storage tanks or sumps

Because the system reacts instantly and accurately, teams no longer need to schedule manual checks or standby personnel just to “watch the pump.” That means workers can focus on skilled labor, project managers get better oversight, and site supervisors have fewer interruptions or emergencies to manage.

Also, in sites with multiple zones—such as high-rise builds or infrastructure projects—the controller can manage several pumps simultaneously through programmable logic, ensuring each area gets water management precisely when and where it's needed.

All of this adds up to:

Fewer delays caused by water accumulation

Reduced staffing costs for manual monitoring

More predictable workflows, especially in fast-moving environments

In short, by putting the system in control of pump operations, your team gains time, accuracy, and flexibility—three things every construction site could use more of.

Can Smart Pump Control Really Save Energy and Reduce Costs on Construction Sites?

Pumping operations might not always be the first thing that comes to mind when thinking about energy efficiency on a construction site—but they often contribute far more to electricity bills than expected, especially when pumps are left running longer than necessary or at full power regardless of flow demand.

In traditional setups, pumps are either manually switched on or run based on basic timers. This means they're often overused during low-demand periods, like overnight or between concrete pours, and under-optimized when conditions actually require more precise control.

An automatic water pump controller addresses these issues by making pump activity demand-driven and adaptive.

Here's how it helps reduce costs:

It adjusts pump speed and duration in real time, using sensor feedback on water levels, system pressure, and flow rate. When inflow slows down, the controller reduces the pump’s intensity—or pauses it entirely—saving electricity without compromising performance.

With Variable Frequency Drive (VFD) integration, the controller can fine-tune the pump’s motor speed to exactly match the load required at any given moment, avoiding energy waste due to overpumping or pressure overshoot.

It can also be programmed with time-based schedules, so that pumps don’t run during low-activity hours unless triggered by an actual need.

For example, on a site where concrete curing happens in several phases throughout the day, water delivery needs may vary widely by time. Instead of running pumps at a constant rate “just in case,” the controller ensures water is delivered only when scheduled—and in the exact quantity needed.

This results in:

Lower utility bills by cutting down on excessive pump runtime

Less wear on equipment, which also saves on repair and replacement costs

Reduced noise pollution, especially helpful in urban or nighttime work environments

Over time, many site managers find that the return on investment for a controller isn't just about energy—it’s about the total reduction in operating friction, from fuel consumption in generator-powered sites to fewer reactive maintenance calls.

So, to answer the question: yes—smart pump control can absolutely reduce energy usage and operating costs. And it does so not by asking your team to work harder, but by letting your system work smarter.

How Does Pump Automation Help Prevent Equipment Failure and Downtime?

Construction sites operate under tight schedules—and unexpected equipment failure is one of the fastest ways to throw those schedules off track. When it comes to pumps, issues like dry running, pressure surges, or continuous cycling are common causes of premature wear, overheating, or even complete breakdowns. These failures often occur not because the pump is poorly made, but because it's not being operated under the right conditions.

That's where an automatic water pump controller plays a crucial role in protecting your equipment and minimizing downtime.

At its core, the controller continuously monitors key operational parameters—such as water level, pressure, power input, and flow consistency—and responds instantly when something starts to go wrong.

For example:

If water levels in a dewatering pit drop below a safe threshold, the controller shuts the pump off to prevent dry run, which could otherwise burn out the motor.

If abnormal back pressure or rapid cycling is detected, it pauses the system and issues an alert—before a valve gets damaged or a seal fails.

If the pump starts drawing more current than expected, indicating potential overload or blockage, the system reacts immediately—avoiding overheating or fire risk.

In practice, this means pumps are no longer running blind. Instead, they're part of a feedback-driven system that protects them from being overworked or misused.

This level of control is especially helpful in environments where:

Site conditions change rapidly (e.g., during excavation or foundation laying)

Different crews operate different parts of the system at different times

Maintenance resources are stretched, making proactive protection more valuable than reactive repairs

Beyond damage prevention, the controller can also log pump behavior over time—giving site supervisors valuable data to schedule predictive maintenance rather than waiting for failure. Trends in startup time, power draw, or cycle frequency can all help detect wear-and-tear before a breakdown occurs.

The result?

Fewer unscheduled stops

Less money spent on emergency repairs or replacements

More confidence in your equipment’s ability to perform under pressure

Ultimately, smart automation doesn't just improve how a pump works—it safeguards your entire water system investment, keeping the job site productive and the project on track.

Is It Time to Upgrade Your Construction Site's Pumping System?

Keeping a construction site productive and safe requires more than manpower and machinery—it requires smart systems that work with your crew, not against them. Water pump automation is one of the simplest yet most effective upgrades you can make to gain better control over your time, costs, and risk.

An automatic water well pump controller brings measurable improvements in:

Real-time responsiveness and reduced manual oversight

Optimized energy use and cost savings

Prolonged pump life and reduced maintenance interruptions

It's not about replacing people—it's about helping your team work smarter, avoid avoidable problems, and stay ahead of the unexpected.

Why Choose JNN Automatic Water Pump Controllers?

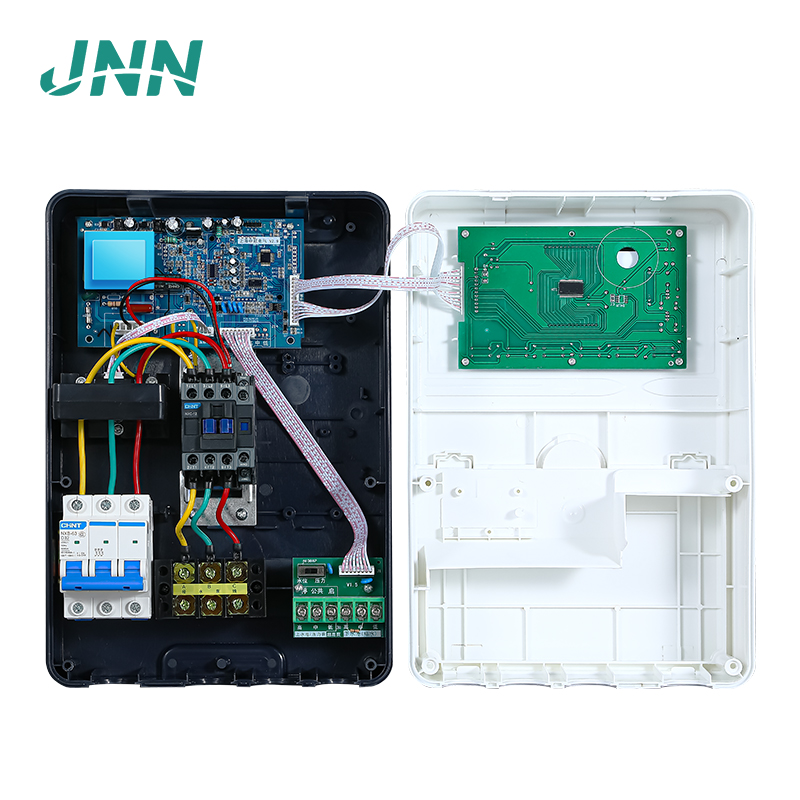

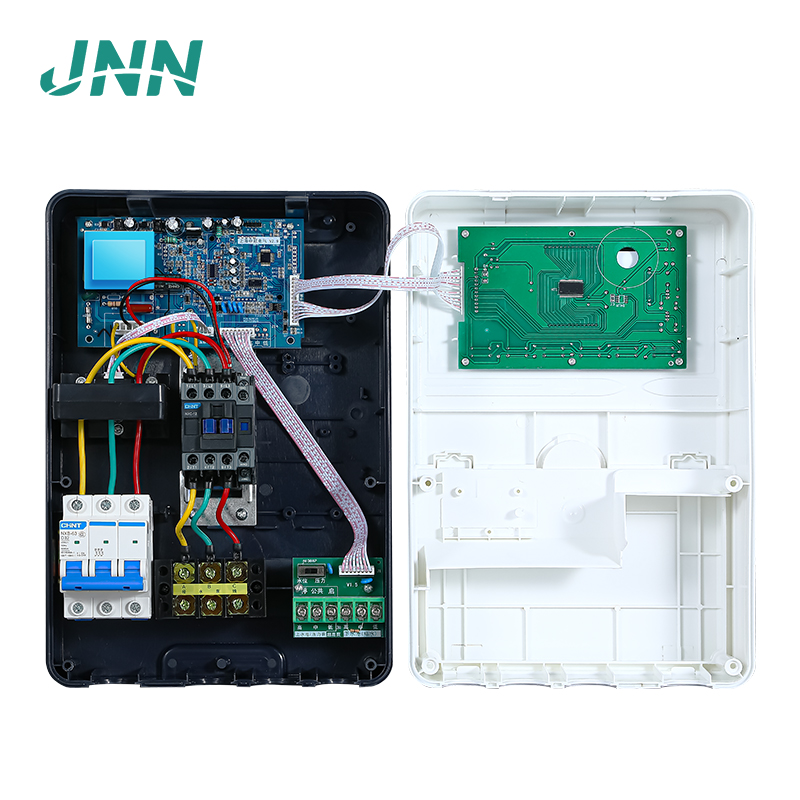

At JNN, we design intelligent, reliable automatic water pump controllers built specifically for construction environments. Our systems offer:

✅ Real-time sensor integration

✅ VFD compatibility for energy-efficient operation

✅ Dry-run and overload protection

✅ Remote access and system diagnostics

Whether your site needs efficient dewatering, flow control for curing, or smart water use across zones, JNN provides tools that help you manage water—without wasting time, energy, or resources.

Explore JNN's smart controller solutions today—and see how your site can work faster, safer, and more efficiently.