Water is the heartbeat of countless systems — from construction sites to factories, from agricultural irrigation to high-rise buildings. And behind the scenes, ensuring consistent water flow, protecting equipment, and minimizing waste is a piece of technology that often gets overlooked: the automatic water pump controller.

If you’ve ever dealt with pump systems manually — or have had to troubleshoot pump failures, tank overflows, or dry-run damages — then you’ll understand how essential intelligent pump control has become. In this guide, we’ll explore what an automatic water pump controller does, why it matters, and how to choose one that fits your system. And most importantly, we’ll look at how the right controller, like those from JNN, can streamline operations, reduce maintenance headaches, and protect your bottom line.

Table of contents

What Is an Automatic Water Pump Controller?

Why Manual Control Systems Are Falling Behind

Where Are Automatic Pump Controllers Typically Used?

What to Look for in a Quality Automatic Water Pump Controller

The Financial and Operational Benefits of Automation

Choosing the Right Controller: Practical Examples

Final Thoughts: Simplify, Protect, and Save with JNN

What Is an Automatic Water Pump Controller?

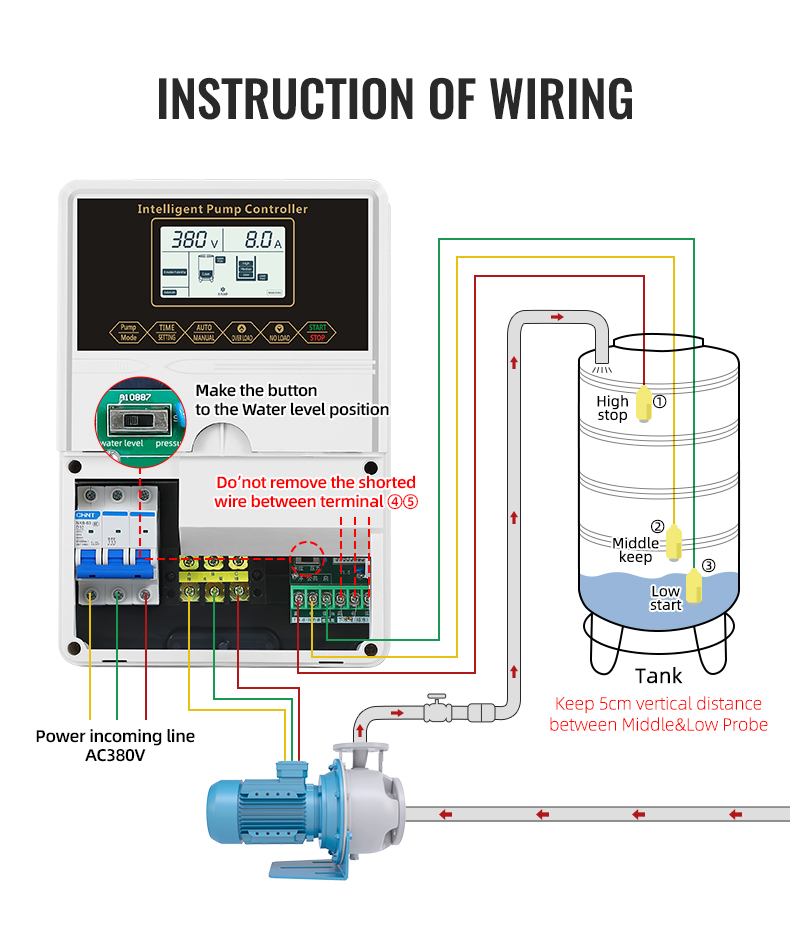

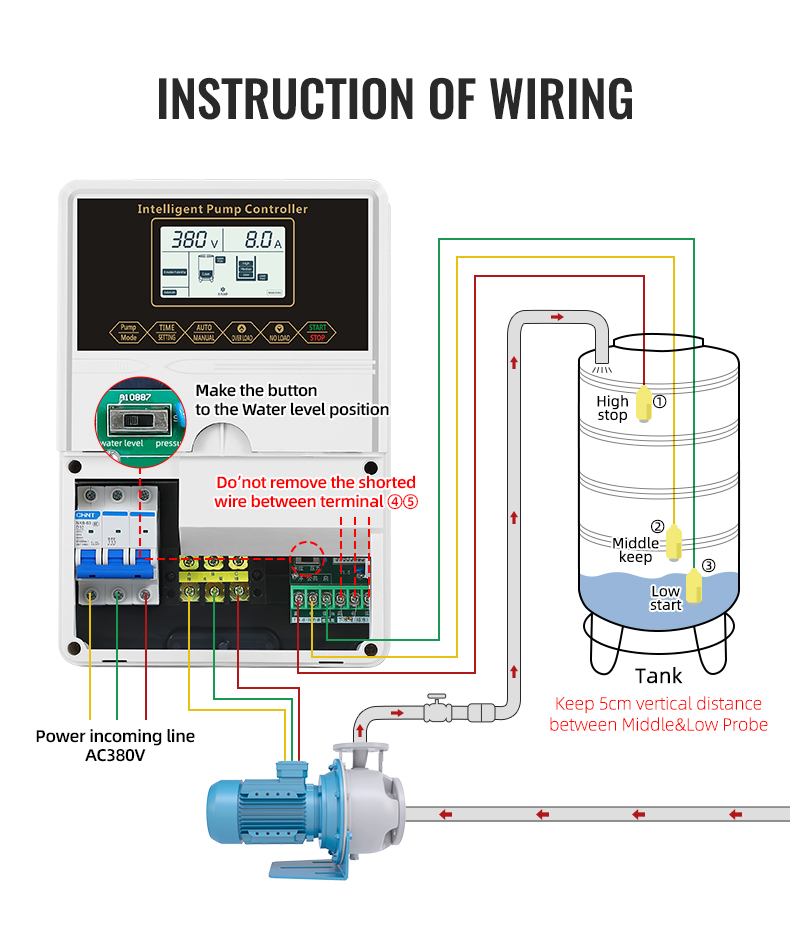

Let’s keep it simple. An automatic water pump controller is a smart device that automates the process of switching water pumps on or off based on predefined conditions — such as water level, pressure, or flow rate. No more manual toggling, no more guesswork.

Whether you're dealing with a sump pump, a deep well system, or an industrial supply tank, the controller acts as the brain behind the operation. It ensures that water flows when it's needed and that pumps shut off when they shouldn't be running.

Key Functions at a Glance:

Auto Start/Stop based on tank level, pipeline pressure, or timer.

Dry-run Protection to prevent pump burnout.

Overload & Short-circuit Protection for electrical safety.

Pressure Regulation for steady flow in multi-outlet systems.

Remote Monitoring/Control (available in advanced models).

Deeper Dive: Why Automation Matters

In many systems, water usage isn’t static — it changes with the time of day, the process load, or environmental conditions. Without automated control, there’s often a lag between water demand and pump activation, leading to inefficiency, delays, or even safety hazards. Imagine a system where a water tank fills up during the night when no staff is present — without an automatic controller, the overflow could go unnoticed for hours.

Furthermore, modern automatic controllers are no longer simple on/off switches. Many now incorporate microcontrollers, digital signal processing, and sensor fusion technology, allowing them to adapt in real time. Some even feature learning algorithms that adjust pump timing based on past usage patterns, delivering smarter control over time.

JNN’s automatic water pump controllers are built with this kind of intelligence and versatility. Whether installed in a compact single-pump system or a more complex multi-stage setup, they seamlessly adapt and simplify the operation without requiring constant oversight from your team.

❌ Why Manual Control Systems Are Falling Behind

Many teams still rely on traditional pump systems where someone must manually operate pumps or monitor levels. While this can work in low-scale setups, it introduces several risks in larger or remote applications:

Human Error: Forgetting to turn off a pump can lead to overflows, flooding, or even equipment burnout.

Inconsistent Water Flow: Manual operation often results in pressure fluctuations and system inefficiency.

Maintenance Issues: Pumps operating dry or under stress degrade faster.

Labor Costs: Frequent human intervention eats up time and resources.

Let’s Be Honest: Manual Control Is a Hidden Cost

At first glance, manually managing a pump system might seem cost-effective. You assign a technician to check water levels and flip a switch when needed — simple, right? But over time, these repetitive tasks accumulate hidden costs. Think about the labor hours spent on monitoring. Think about the fuel and time wasted driving out to remote sites just to turn a pump on or off. And think about the late-night emergencies that could’ve been avoided with timely pump shutoff.

There’s also the issue of delayed response. Pumps often need to act within seconds to prevent system disruption. A few minutes of delay caused by a human response — or even worse, a forgotten check — could lead to flooding, water loss, or overheating. In highly regulated industries, these lapses can mean compliance violations or even fines.

Furthermore, relying on manual operation creates a single point of failure. If the responsible technician is unavailable, or if communication breaks down, the entire system becomes vulnerable. Automation, on the other hand, creates consistency and resilience. With an automatic controller, you gain reliability that doesn’t clock out at 5 PM or take weekends off.

By upgrading to an automatic water pump controller like those offered by JNN, many companies have reported a 30–50% reduction in operational disruptions, not to mention fewer maintenance calls and better energy use. It’s a classic case of working smarter — not harder.

Where Are Automatic Pump Controllers Typically Used?

While the technology applies across industries, it’s most beneficial in applications where water is being pumped frequently or in high volume. Let’s take a closer look at a few real-world scenarios.

1. Industrial Cooling Systems

In many manufacturing facilities, cooling systems are crucial to maintaining machinery at safe operating temperatures. An automatic controller helps regulate flow to keep coolant tanks filled while preventing overflow or damage to the pump motors.

2. Construction Site Water Removal

Heavy rains and groundwater are common issues at construction sites. A controller can ensure sump pumps activate automatically when water levels rise, helping keep foundations dry and construction timelines on track.

3. Agricultural Irrigation

With variable water demand and fluctuating weather, farms need water on demand. Controllers help irrigate fields efficiently while avoiding waste and protecting pump systems from running dry.

4. High-rise Building Water Supply

In multi-story buildings, maintaining consistent water pressure is complex. Controllers with pressure sensing capabilities help regulate water distribution while ensuring the booster pumps don’t overwork.

Going Deeper: Why These Applications Benefit So Much

Let’s break it down. In industrial environments, time is money. Downtime caused by overheating or inconsistent water flow can halt entire production lines. With JNN's controllers, cooling systems can operate on a closed loop — automatically adjusting based on real-time temperature and flow readings, minimizing manual oversight and reducing energy spikes.

On construction sites, particularly those below ground level or in flood-prone zones, time-sensitive water removal is critical. Waiting for someone to manually turn on a sump pump can mean water pooling around foundations or inside equipment zones. With an automatic pump controller, the system responds instantly — even if the site is unmanned.

In agriculture, things get even more unpredictable. Irrigation often depends on external factors like rainfall, temperature, and soil condition. Farmers can’t always be there to start or stop pumps. With a reliable controller, water delivery becomes consistent, reducing crop stress and helping optimize yield with fewer wasted resources.

And in urban infrastructure, such as office buildings, hospitals, and apartment complexes, water pressure inconsistencies create customer complaints and even health risks. Automated systems help smooth out supply without requiring constant attention from building maintenance staff.

Whether your water system is above ground or below, local or remote, simple or complex — there’s a strong case to be made for automation. And it’s in these use cases that the JNN automatic water pump controller shows its strength: adaptable, rugged, and engineered for real-world reliability.

What to Look for in a Quality Automatic Water Pump Controller

Not all controllers are created equal. Here are the features that genuinely matter — especially in demanding environments:

✔️ Compatibility

Make sure the controller supports the type and capacity of your pump (AC or DC, submersible or centrifugal). JNN offers a range of models to suit different pump types, voltages, and motor sizes.

✔️ Multiple Sensor Inputs

The more inputs it supports — float switches, pressure sensors, flow sensors — the more control you have over your system.

✔️ Built-in Protection Features

Look for overload protection, phase failure detection, and dry-run protection. These features extend pump life and reduce maintenance needs.

✔️ Remote Access (Optional)

For setups spread across multiple sites or in remote locations, IoT-enabled controllers can provide app or web-based monitoring — allowing your team to stay on top of things even when off-site.

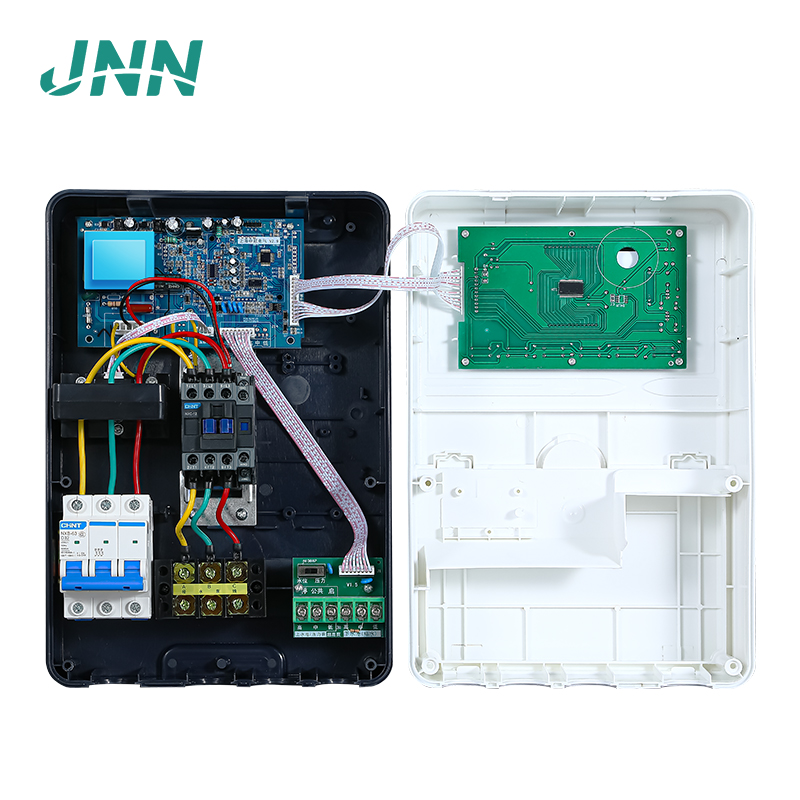

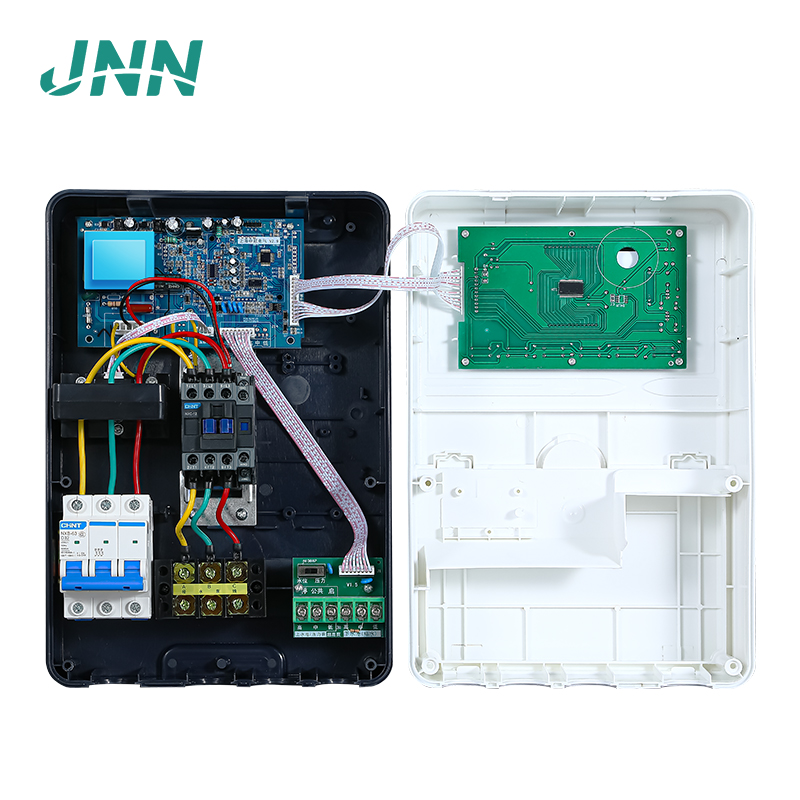

✔️ Easy Installation and Interface

Time is money. Choose a controller that’s clearly labeled, includes a setup manual, and doesn’t require rewiring your entire pump system.

More Than Features — It’s About Fit and Reliability

It’s not just about ticking boxes. A great controller doesn’t just have more features — it has the right features, presented in a way that makes your life easier. That’s why selecting a product from an experienced brand like JNN makes a difference.

For instance, JNN’s controllers are designed to work across a wide voltage range, from low-voltage solar-powered pumps to heavy-duty industrial motors. This means you don’t need different controllers for every site — a single solution can adapt to various use cases.

Many engineers also underestimate the importance of environmental protection. Is the controller waterproof? Dustproof? Rated for outdoor use? In real-world operations, especially in agriculture or construction, controllers are often exposed to the elements. That’s why JNN ensures their enclosures meet IP65 or higher ratings, so you’re not replacing hardware every rainy season.

Also, user interface matters more than most think. A cluttered display, confusing button labels, or inconsistent status indicators can lead to costly mistakes. That’s why JNN’s interfaces are intuitive, often featuring multilingual options, large LED indicators, and step-by-step configuration wizards.

Bottom line? Look beyond the spec sheet. Choose a controller that offers the balance of functionality, durability, and ease-of-use — because in the field, simplicity and reliability often matter more than fancy bells and whistles.

The Financial and Operational Benefits of Automation

Investing in an automatic water pump control box often pays for itself within months — not years. Here’s how:

Reduced Maintenance Costs

By preventing dry-runs and overloads, your pump motors and pipelines stay in better condition, requiring fewer repairs or replacements.

Improved Energy Efficiency

Smart controllers only run pumps when needed, cutting back on electricity consumption and lowering your power bills.

Lower Labor Dependency

Once configured, the system needs minimal human intervention, freeing your team to focus on more strategic tasks.

Safer Operations

Electrical safety features, fail-safes, and alarms ensure both equipment and workers are better protected.

Data-Driven Decision Making

Some controllers offer insights into pump cycles, runtime, and errors — helping you optimize performance or plan future expansions more effectively.

Let’s Talk Numbers — Why the ROI Is Real

Consider this: a mid-sized facility running a 3HP pump for 8 hours a day can save up to 15–20% on electricity costs just by switching to an intelligent controller with smart scheduling and load balancing. That alone can mean hundreds, even thousands of dollars saved annually — and that’s just one pump.

Now think bigger. Factor in reduced downtime, fewer emergency service calls, and less frequent pump replacement. Suddenly, your ROI isn’t just compelling — it’s inevitable.

Take labor costs, for example. Suppose a technician is paid $25/hour and spends just 30 minutes each day managing pumps. That’s over $3,000/year in labor. With automation, that time can be cut down to near zero. Over a fleet of sites or systems, that becomes tens of thousands of dollars.

Operationally, automation also leads to predictable outcomes. Pumps no longer run when dry, tanks don’t overflow, and flow rates stay consistent. That predictability helps teams plan better and avoid last-minute fixes or disruptions — something particularly valuable in tightly scheduled environments like production lines or construction projects.

In industries where margins are tight and efficiency is king, having a smart pump controller is less of a luxury and more of a strategic investment. It’s not just about saving money — it’s about operating with less risk, more control, and greater confidence.

JNN’s pump controller systems are engineered with these benefits in mind — helping companies operate smarter from day one, without a steep learning curve or major infrastructure changes.

Choosing the Right Controller: Practical Examples

Here are three simplified scenarios to help illustrate the value of a good automatic water pump controller:

Example 1: Concrete Manufacturing Plant

A concrete plant uses multiple water storage tanks for batching processes. With JNN’s automatic controller, the pumps activate based on tank levels, maintaining water supply without flooding the mixing area. The team reduced downtime by 30% and extended pump lifespan by over 18 months.

Example 2: Remote Agricultural Irrigation

A farm located in a semi-arid region uses groundwater pumps for irrigation. Manual operation previously caused dry-run failures. Installing JNN's controller with dry-run protection and float-level triggers eliminated pump damage and reduced water usage by 22%.

Example 3: High-Rise Office Building

To ensure consistent water supply across 20 floors, the building management adopted JNN’s pressure-based controller, which regulates booster pumps automatically. The system ensures comfort for occupants while optimizing electricity usage during off-peak hours.

Why Real-World Use Cases Matter

It’s one thing to read about technical specifications; it’s another to see how a product performs under pressure. These examples show the practical versatility of automatic water pump controllers across different sectors, and how choosing the right one can directly impact operational stability and bottom-line results.

In the concrete plant, time is everything. A single delay in batching due to insufficient water can halt the production process and create a domino effect of missed deliveries. Before automation, operators had to physically monitor water levels and react in real-time. With JNN's system, the process is now seamless — reducing stress on staff and minimizing waste.

In the farming scenario, dry-run failures were not only costing the farmer money in repairs but also creating unpredictable irrigation schedules. This affected crop yield and overall resource planning. JNN’s controller brought predictability, which is gold in agriculture. The farmer also appreciated the low-maintenance setup — no need to check the well every morning.

And in the high-rise building, the benefits weren’t just operational — they were also tied to customer experience. Inconsistent water pressure led to tenant complaints, particularly during peak usage hours. By adding JNN’s intelligent controller with built-in pressure sensors, the facility team achieved steady pressure regulation and reduced pump cycling frequency, which also extended pump motor lifespan.

These stories prove a crucial point: the right automatic water pump controller doesn’t just “do the job” — it transforms how the job is done. And with JNN’s customizable range, there’s a solution for nearly every challenge.

The world is moving toward energy-efficient, remotely monitored, and sustainable systems. Pump controllers are evolving too — integrating cloud connectivity, AI-based diagnostics, and auto-calibration features. JNN is at the forefront of this shift, developing products that adapt to modern needs while remaining reliable and rugged.

With stricter energy regulations and growing demand for uptime, investing in smart pump control is no longer optional — it’s essential.

Final Thoughts: Simplify, Protect, and Save with JNN

An automatic water well pump controller may not be the flashiest component in your system, but it’s definitely one of the most valuable. It prevents costly mistakes, improves efficiency, and gives you peace of mind knowing that your pumps — and the water they move — are under control.

JNN offers a line of intelligent, durable, and easy-to-integrate automatic pump controllers designed to serve a wide range of industries. Whether you're upgrading your current setup or building something new, our solutions are here to help simplify your water management.

Explore JNN’s automatic water pump controller series today and see how much smoother your operations can run.