Product Description

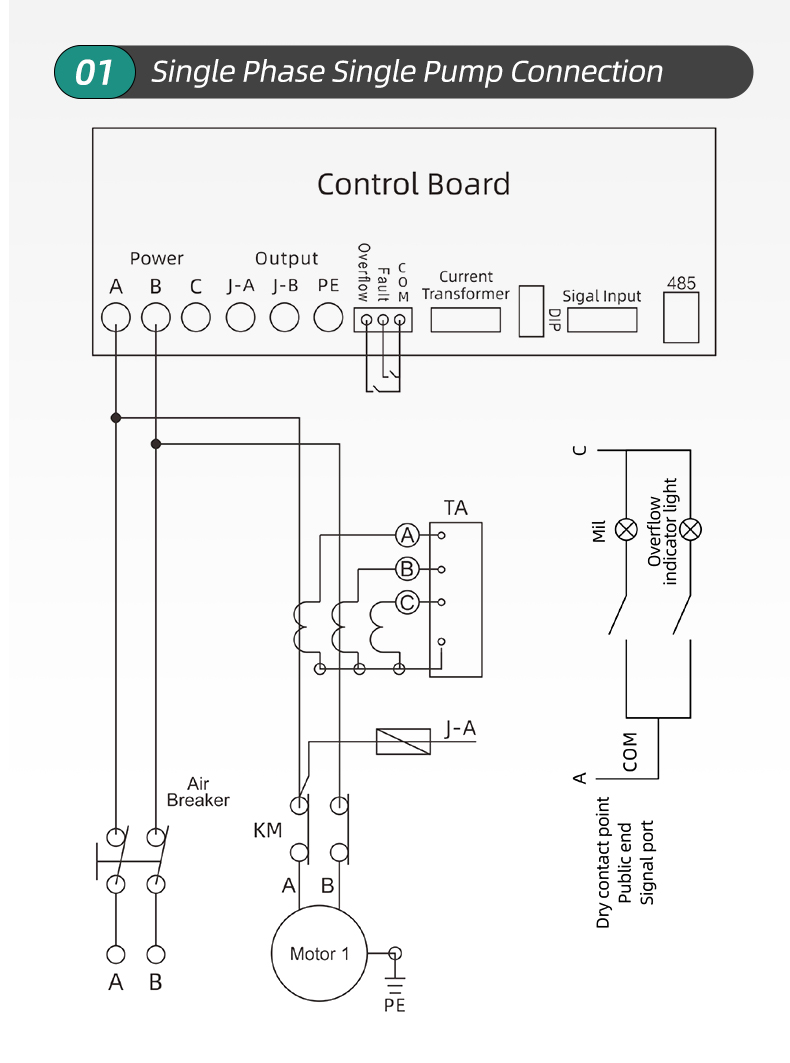

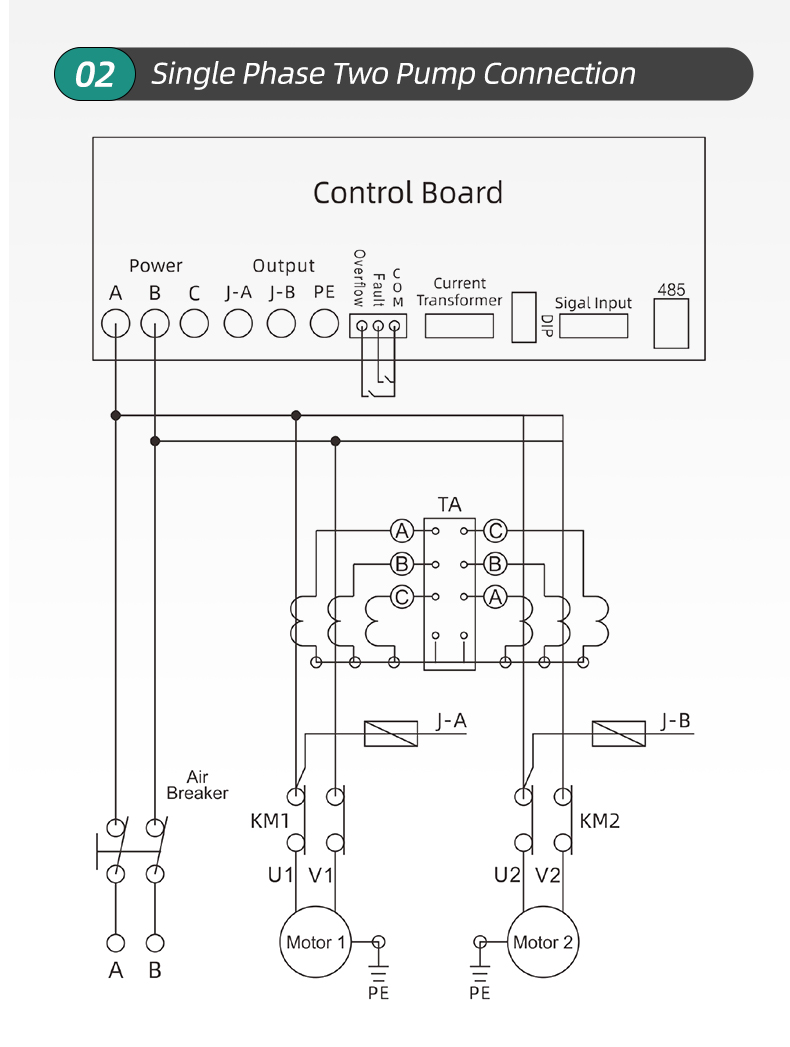

The split water pump control panel is an intelligent and economical system designed for pumps and motors,can be encased to constitute the whole controller set.Pump Control Panel that start and stop pumps and devices that allow operator monitoring and control. Suitable for Surface pump,Sewage Pump,Booster pump,Submersible pumps and etc.

Typical application scenarios:

-Agricultural irrigation/ pumping

-Pressure Booster Systems

-Waste water treatment

-Water Tanks/Wells

-Drainage System

-Cooling Towers

-Flood Control

-Fishing Boat

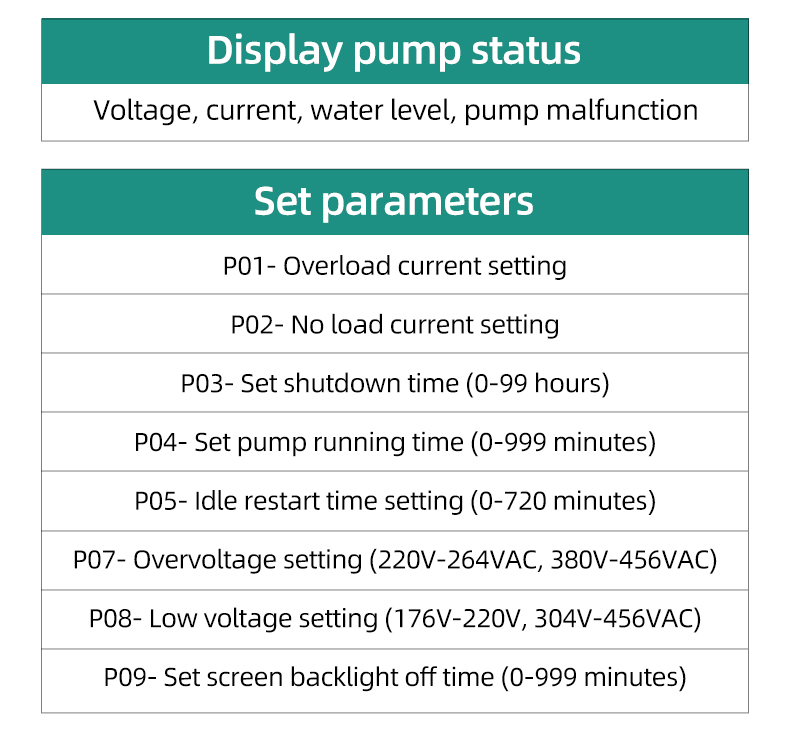

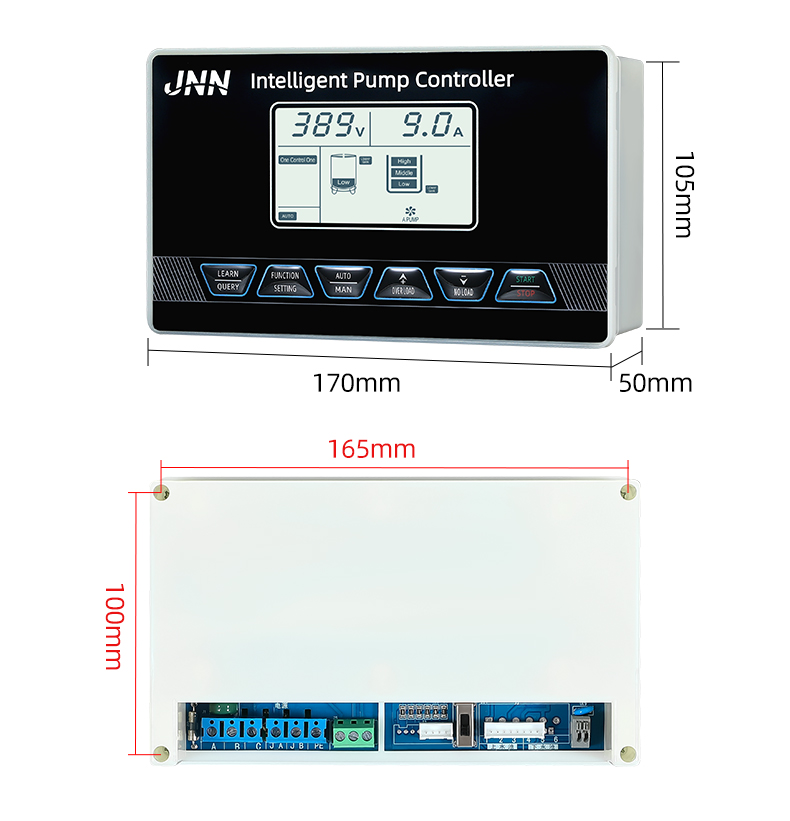

Specifications of water pump controller

| Type | D1F |

| Model | D1F-11000 | D1F-30000 |

| Rated Power | 0.75-11KW | 11-30KW |

| Rated Input Voltage | 380+10%/50Hz or 60Hz |

| Qty.of Controlled Pump | Single pump |

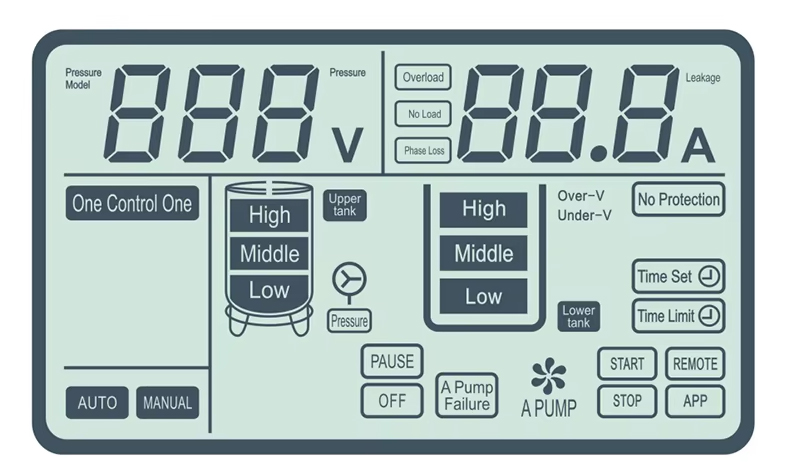

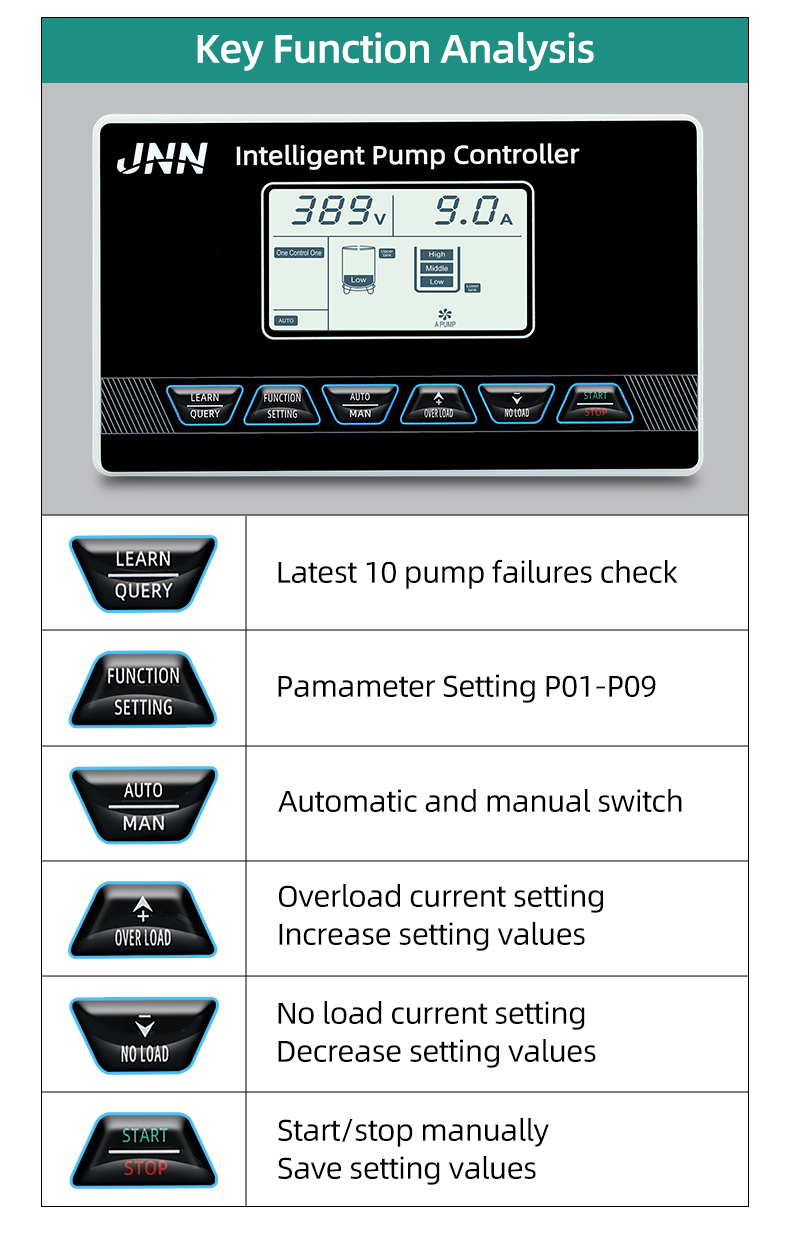

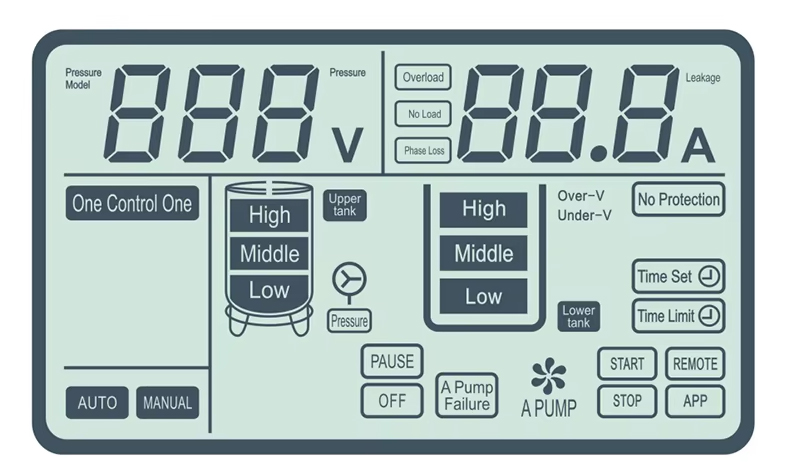

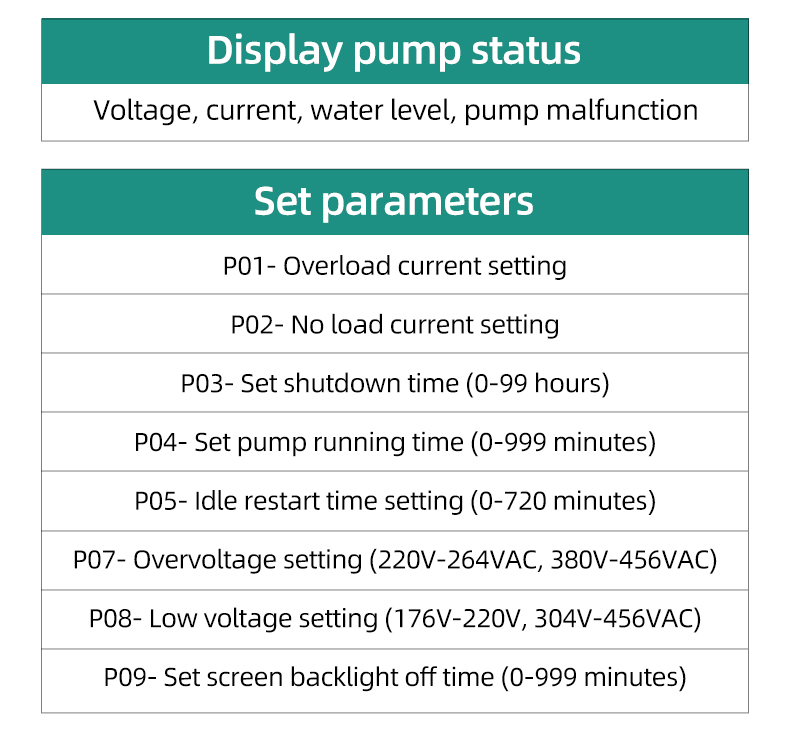

| Display | LCD display |

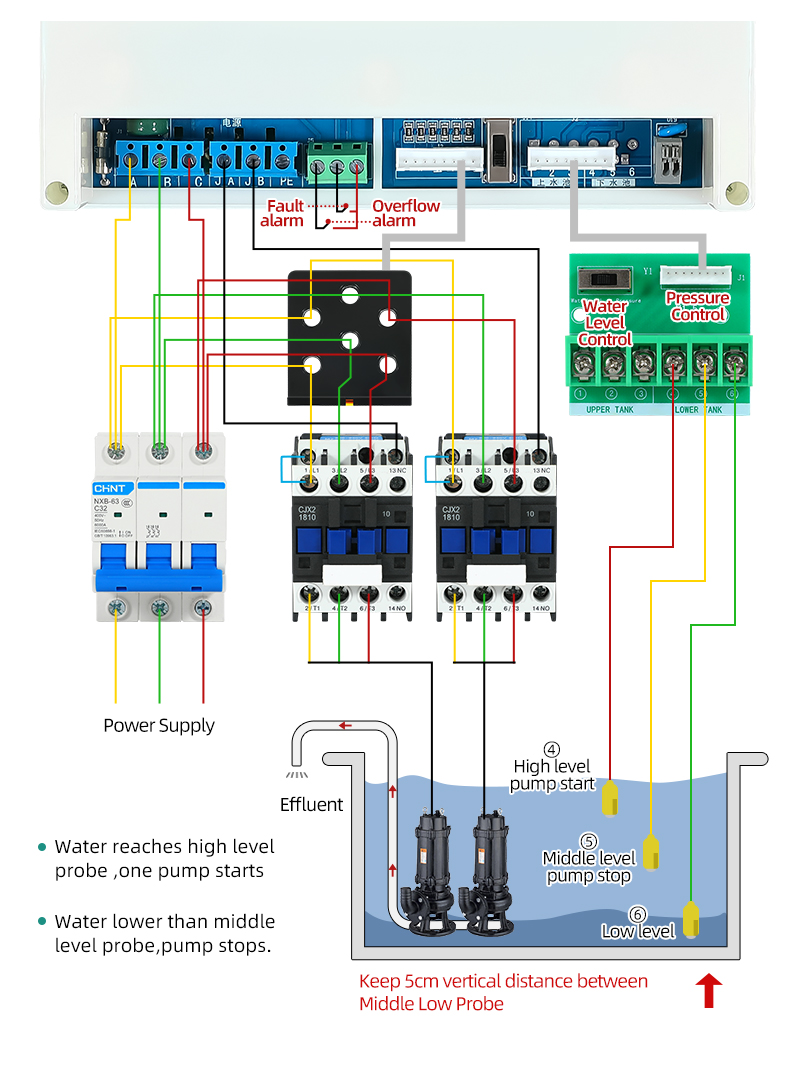

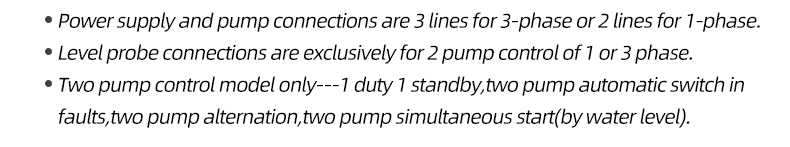

| Signal Transmission Mode | Level float switch

Level probe

Pressure switch

Electric contact pressure gauge |

| Water Level Indication | High/Middle/Low |

| Max.Control Distance | ≤2000m without strong electric and electromagnetic fields |

| Over/under-voltage Range | 304V-456V(adjustable) |

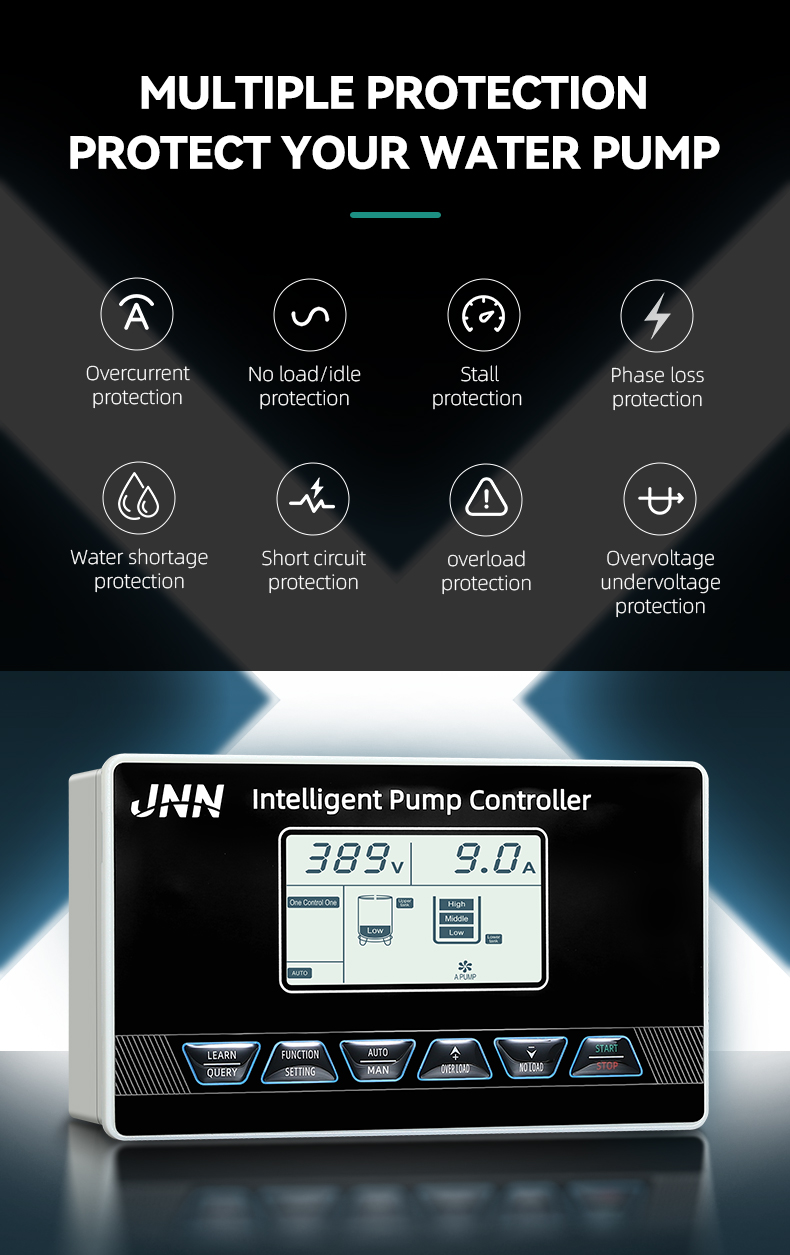

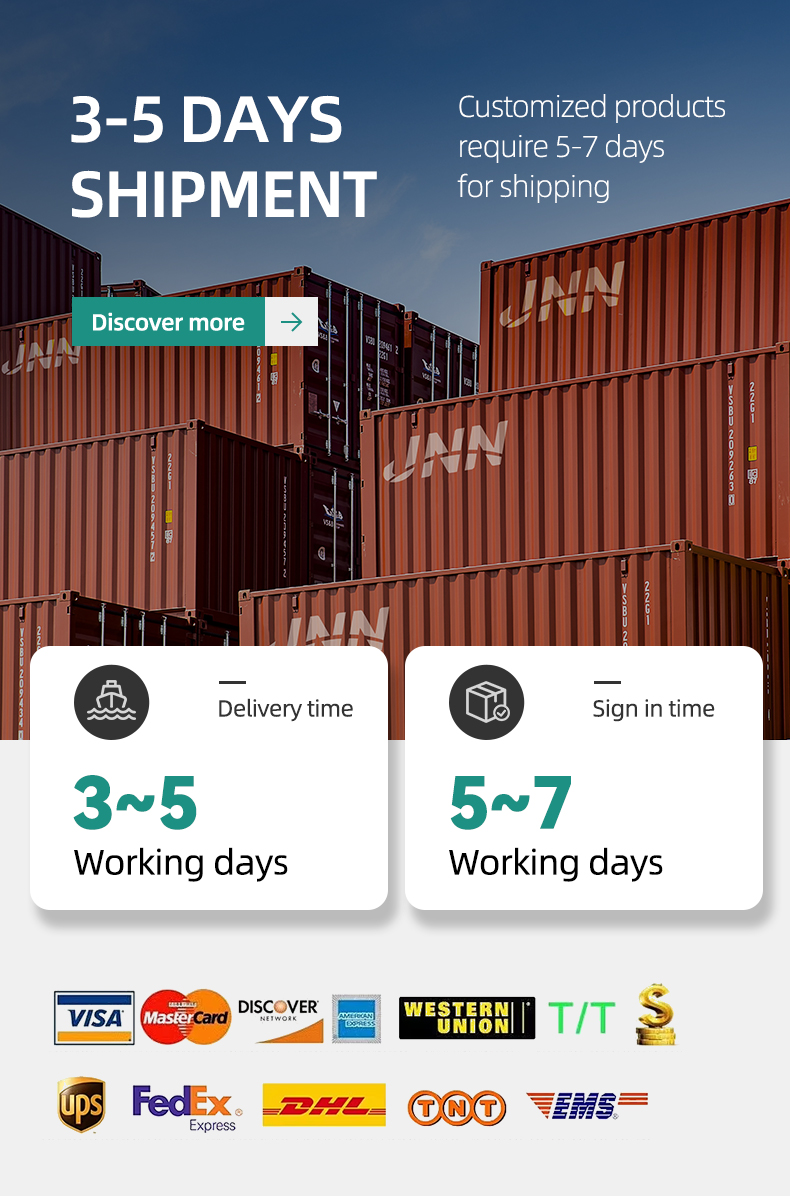

| Protections | Pump stalled protection

Dry run protection

Over-load protection

Under-voltage protection

Over-voltage protection

Open phase protection

Short circuit protection |

| Main Functions | Time setting

Fault detection

Anti-rust inspection

Automatic restart after power recovery |

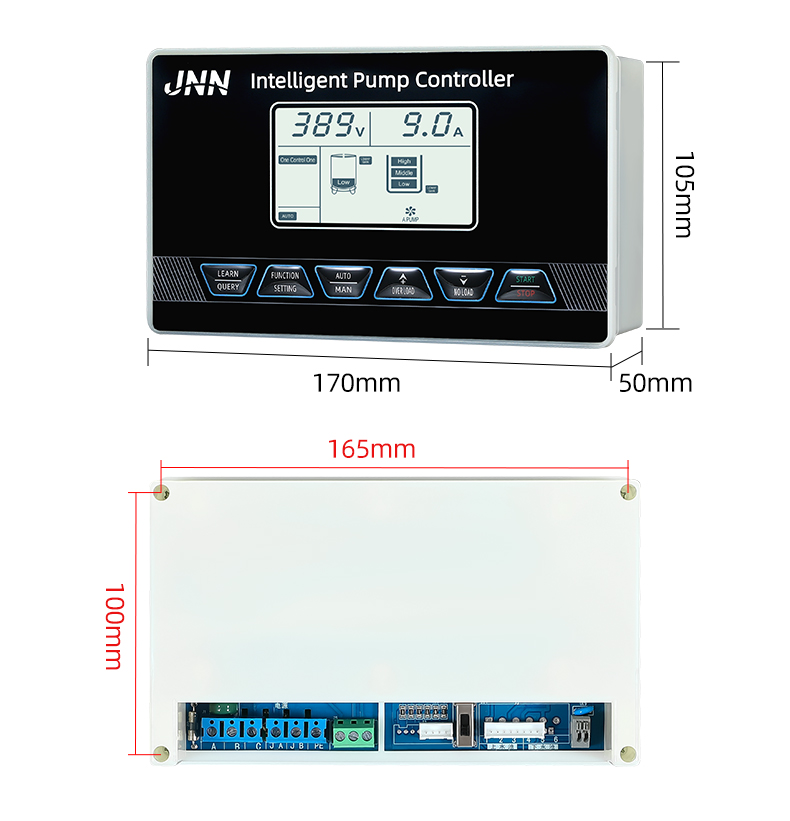

| Product Size | 170x120x50mm |

Working temperature

Working humidity

Degree of protection

Install position | -25ºC-- +55ºC

20%--90%RH, no drips concreted

IP22

Wall mounting |

1)How to convert HP into KW ?

The conversion formula as :1HP=0.74KW

for example: 3HP=3x0.74KW=2.22KW.

2)How to choose the power of your pump controller?

Normally we need choose bigger power to run the water pump or motors,.If the pump rated power is 4KW,Pump controller should choose 7.5KW.For Submersible pumps which used in the deep well,please check with us first .

3)Can I have the samples of your pump controller ?

Yes, we can send you the pump controller samples for your testing .

4)Can you provide OEM or ODM ?

Yes,we can make the orders according to your detailed request.

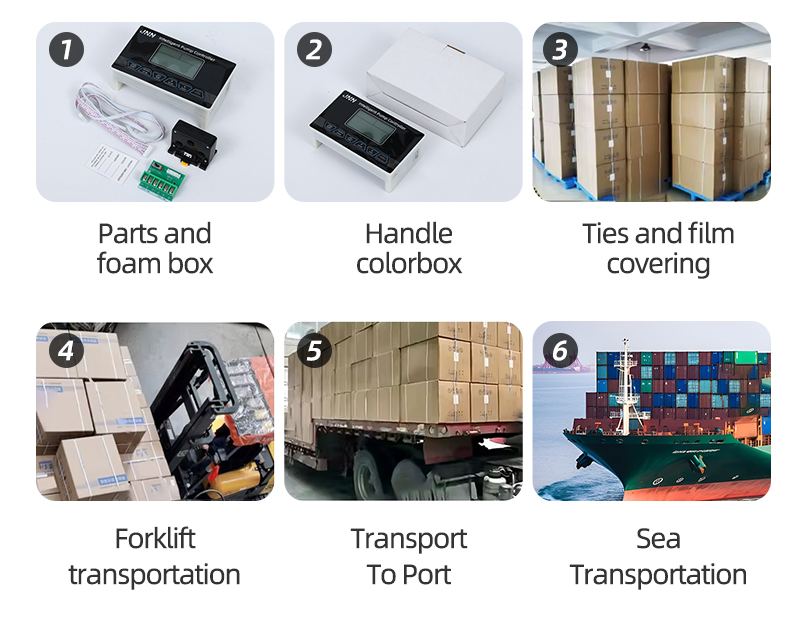

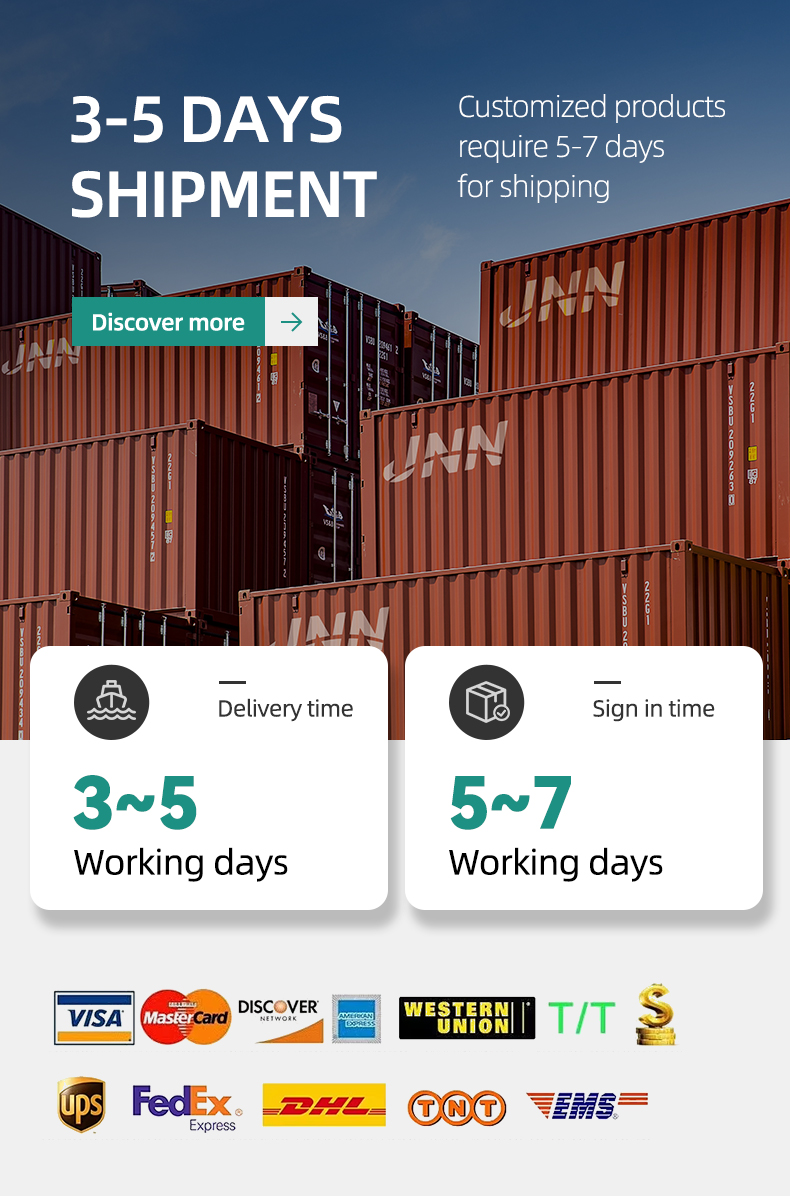

5)what is your delivery time?

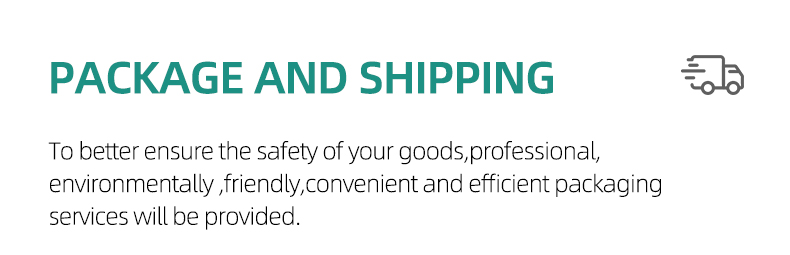

It takes 3-5 days for sample orders,and 15-20 days for orders