Table of Contents

How Does an Automatic Water Pump Controller Work?

Why Are Manual Pump Systems No Longer Enough?

What Features Should You Look for in a High-Quality Controller?

Can It Really Save Time and Money?

Final Thoughts: Why Now Is the Right Time to Upgrade

In today's fast-paced industrial and commercial environments, managing water usage efficiently isn't just a convenience — it's a necessity. Whether you're overseeing agricultural irrigation, construction site dewatering, or complex factory systems, an automatic water pump controller can dramatically simplify your operations and protect your equipment. But what exactly does it do, and why are so many businesses switching from manual systems?

Unlike traditional setups that rely heavily on hands-on control, automatic controllers bring consistency, safety, and convenience into water system management. They respond in real-time to changing water levels or pressure conditions, helping ensure your processes stay uninterrupted — even during off-hours or staffing shortages. And as environmental regulations and operational costs tighten, having a controller that helps conserve water and electricity makes both economic and environmental sense. It's not just about automation — it's about working smarter with your resources.

How Does an Automatic Water Pump Controller Work?

An automatic water pump control box is like a smart assistant for your water system. Instead of relying on human monitoring or manual switching, it automates the process of turning the pump on and off based on preset water levels, pressure values, or flow rate readings.

For example, when the water level in a tank drops below a certain point, the controller can activate the pump to refill it. Once the desired level is reached, it shuts the pump off — no intervention needed. Some advanced models can even monitor dry-run conditions or power fluctuations to prevent pump damage.

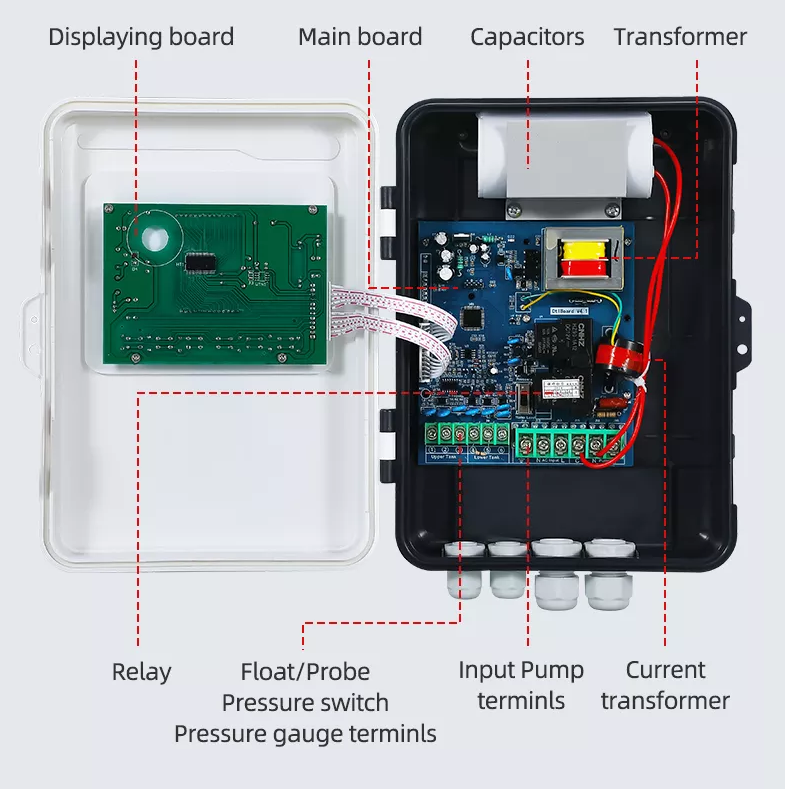

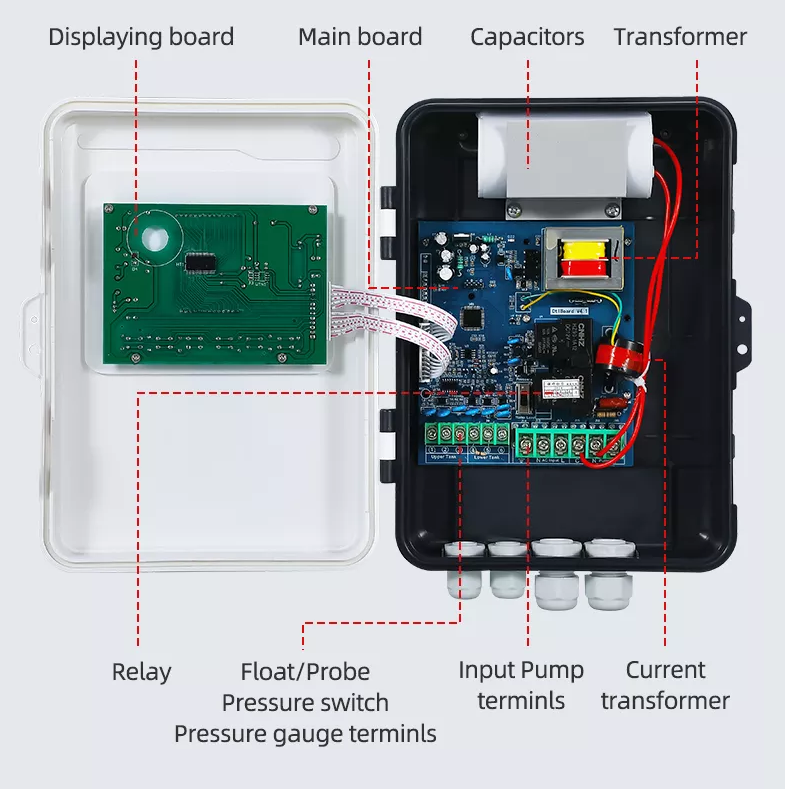

Behind the scenes, the controller constantly reads input from sensors — such as float switches, pressure transducers, or level probes — and makes real-time decisions to start or stop the pump. This not only reduces the chance of human error, but also ensures the pump operates within its optimal range. With newer models supporting programmable settings and multi-stage pumping, businesses gain better precision and control over how and when water is moved, ultimately improving both safety and efficiency.

Why Are Manual Pump Systems No Longer Enough?

Manual systems still exist, but they come with a high price: human error, time consumption, and inconsistent results. If a staff member forgets to turn off a pump, it can cause overflow, motor burnout, or wasted electricity. On the other hand, failing to start the pump in time could result in water shortages or process delays.

Automatic controllers eliminate this uncertainty. They're designed to:

Operate 24/7 with minimal human supervision

Ensure consistent water delivery

Reduce the risk of pump wear and tear

Extend the system's operational lifespan

Manual control also becomes increasingly impractical as systems grow in size or complexity. Imagine managing dozens of pumps scattered across different zones, each requiring careful timing and monitoring — it's a recipe for inefficiency. Automatic controllers centralize and simplify this process, making it easier to manage large-scale operations with fewer resources. They also allow your team to focus on higher-value tasks rather than constantly checking water levels or flipping switches. In short, automation doesn't just replace manual work — it enhances how the whole system performs.

What Features Should You Look for in a High-Quality Controller?

Not all water pump controllers are built the same. Depending on your application, you'll want to pay attention to:

Sensor Compatibility – Does it support float switches, pressure sensors, or both?

Voltage and Load Ratings – Can it handle the pump's power requirements?

Environmental Durability – Is it waterproof or dustproof for harsh locations?

Control Logic – Does it support multi-stage control or programmable settings?

Some models also feature remote monitoring, which is especially useful for large facilities or off-grid setups. A well-chosen controller isn’t just a switch — it's a control hub for your entire water system.

In more advanced settings, having features like dry-run protection, delay timers, and auto-restart after power failure can be critical. These functions not only prevent damage but also reduce downtime and maintenance costs. It's also worth considering whether the controller can be integrated into a broader system — for example, connecting with a PLC or IoT platform for centralized monitoring. Choosing the right controller is about more than ticking boxes — it's about ensuring the controller can grow with your operation and provide long-term reliability.

Can It Really Save Time and Money?

Absolutely. A good automatic water well pump controller does more than turn a pump on and off — it brings predictability to your operations. Here's how it adds tangible value:

Reduced labor costs by removing manual intervention

Lower energy bills through efficient usage

Fewer emergency repairs caused by pump misuse or dry-run damage

More consistent water supply, improving system reliability

These savings become even more noticeable in environments where pumps operate around the clock or are spread across multiple locations. For instance, in agricultural settings, automated control can ensure optimal irrigation without needing staff to work late hours. In construction or mining, it helps avoid flooding by activating pumps automatically during heavy rain. And because it minimizes the risk of equipment failure, it also extends the lifespan of your pumps and reduces the frequency of costly replacements. Over time, the return on investment for an automatic controller is not just clear — it's substantial.

Final Thoughts: Why Now Is the Right Time to Upgrade

With smart infrastructure becoming the norm, adopting technologies like automatic water pump controllers isn't just forward-thinking — it's practical. Whether you're upgrading old systems or building from scratch, adding automation can give you better control, fewer headaches, and improved performance.

In a world where efficiency and reliability are key to staying competitive, delaying automation often means higher long-term costs. By switching to a well-designed automatic controller, you gain peace of mind, reduce downtime, and improve overall system safety — all without constant manual oversight.

If you're searching for a trusted solution that combines precision engineering with field-tested durability, JNN offers a range of automatic water pump controllers specifically built to meet the demands of real-world applications. Designed with both performance and ease of use in mind, JNN helps your water systems run smarter — not harder.