In regions like America, where water conservation and agricultural efficiency are critical, understanding how water pump control systems operate is essential for both residential and commercial purposes. A water pump controller is a vital device that manages the functioning of a water pump, ensuring that it performs optimally while maximizing energy efficiency and extending its operational lifespan.

This article will provide a detailed overview of how water pump controllers work and illustrate how integrating one into your water management system can lead to substantial improvements in energy savings, performance, and longevity. As you will see, upgrading to a JNN Water pump controller could be a smart choice for enhancing your system's efficiency. Let's explore the benefits of adopting these advanced controllers.

The Basics of Water Pump Controllers

In water management systems, water pump controllers help optimize the pump's performance by regulating key parameters such as speed, pressure, and flow. Below, we will explore the different types of water pump controllers and their roles in water systems.

What is a Water Pump Controller?

A water pump control box (water pump controller) is an intelligent device designed to optimize the operation of a water pump by controlling its speed, pressure, and flow based on real-time demand. The primary function of a water pump controller is to enhance the overall performance of the pump system, ensuring that it runs efficiently while minimizing energy consumption and reducing mechanical wear. By continuously monitoring system demands, a water pump controller helps maintain a consistent water supply for a range of applications including residential, commercial, agricultural, and industrial settings.

By managing the pump's operation based on the specific needs of the system, water pump controllers help extend the life of the pump, reduce operational costs, and improve system reliability. This makes them an essential component for any efficient water management system.

Types of Water Pump Controllers

There are two main types of water pump controllers commonly used in water management systems: constant pressure controllers and variable speed controllers. Let's take a closer look at each type.

Constant Pressure Water Pump Controllers

Constant pressure water pump controllers are designed to maintain a consistent water pressure by automatically adjusting the pump's speed in response to fluctuations in demand. These controllers ensure that the water pressure remains steady, minimizing sudden drops or spikes in pressure that could lead to system inefficiencies or wear on the pump components. By stabilizing the pressure, they ensure smooth and reliable water flow, reducing the load on the pump and helping extend its lifespan.

Variable Speed Water Pump Controllers

Variable speed water pump controllers offer a more flexible approach to pump management. These controllers adjust the pump's speed dynamically based on real-time demand, optimizing energy use and improving system efficiency. Unlike constant pressure controllers, variable speed controllers can precisely match the pump’s performance to the actual water flow required, reducing unnecessary energy consumption when full capacity isn’t needed. This results in significant energy savings over time and also helps to prolong the life of the pump by minimizing strain and wear.

How Water Pump Controllers Work?

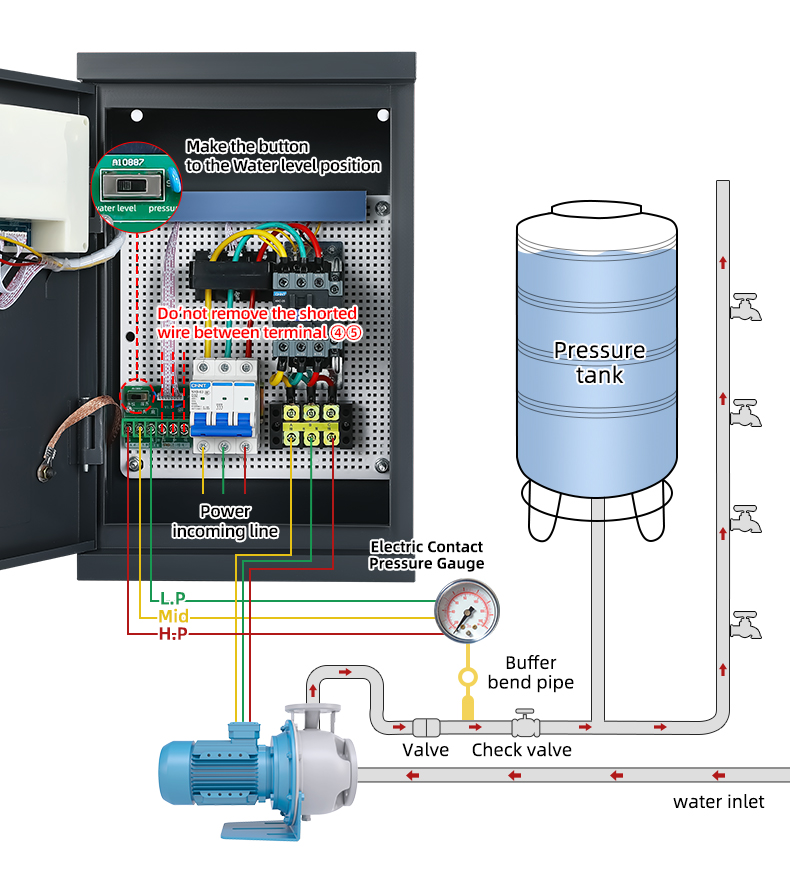

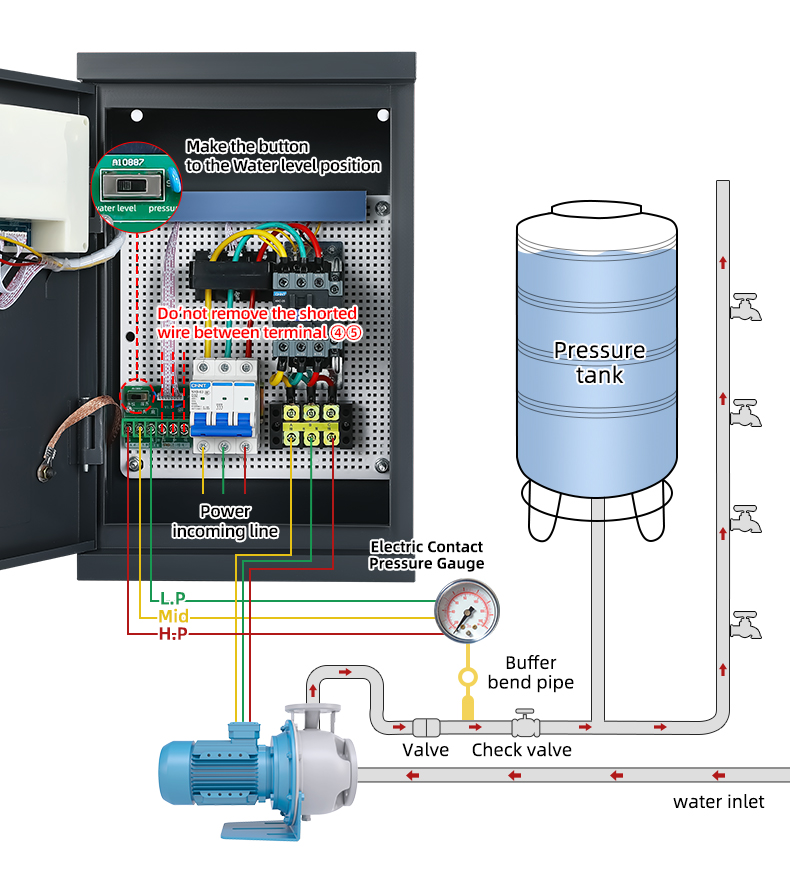

To understand how water pump controllers function, it's important to look at the key components involved. These include pressure sensors, flow sensors, motor control units, and user interfaces, all of which work in tandem to ensure the pump operates efficiently.

Water Pump Controller Components

Water pump controllers are made up of several essential components that collaborate to optimize pump operation:

· Pressure Sensor: This component monitors water pressure levels and sends signals to the controller to adjust the pump's speed as needed. It ensures that the system maintains a consistent pressure and reduces the chances of pressure surges that could damage the system.

· Flow Sensor: This sensor measures the rate of water flow and helps the controller adjust the pump’s speed to match the desired flow. It plays a key role in maintaining efficient water delivery.

· Motor Control Unit: Based on input from the pressure and flow sensors, the motor control unit adjusts the pump motor’s speed to achieve optimal performance while minimizing energy consumption.

· User Interface: This provides a simple way for users to interact with the controller, allowing for easy setup and adjustments to settings such as pressure, flow rate, and operational modes.

Water Pump Controller Operation

When a water pump controller receives input from sensors (such as pressure or flow data), it processes this information and adjusts the pump's speed accordingly. This ensures the system maintains the desired water flow and pressure, even as demand fluctuates. In addition, water pump controllers monitor the pump's overall performance, identifying potential issues such as low water levels or motor overload. By responding to these issues in real-time, the controller protects the pump from damage and ensures reliable operation.

Benefits of Water Pump Controllers

Water well pump controllers provide a variety of benefits, including improved energy efficiency, extended pump life, enhanced system performance, and better protection for your equipment. Let's take a look at how these advantages can translate into long-term savings and increased system reliability.

Energy Efficiency

One of the primary benefits of water pump controllers is their ability to optimize energy use. By regulating the pump’s speed to match demand, these controllers reduce unnecessary energy consumption, which is especially beneficial in commercial and agricultural settings where pumps often operate for long periods. Over time, this leads to significant reductions in electricity costs.

Extended Pump Life

By maintaining consistent flow and pressure, water pump controllers minimize wear and tear on the pump components. This reduces the frequency of breakdowns and the need for costly repairs or replacements, ultimately extending the operational life of the pump. By investing in a water pump controller, you can enjoy a longer-lasting pump and fewer interruptions to your water system.

Improved System Performance

Water pump controllers ensure that the system maintains a steady water flow, reducing the chances of pressure fluctuations or inconsistencies in water supply. This helps improve the overall performance of your system, ensuring that your water pump operates efficiently and reliably, day in and day out.

Enhanced System Protection

Water pump controllers act as a safeguard for your system by continuously monitoring pump performance and detecting issues early, such as low water levels, motor overload, or system leaks. When these problems are detected, the controller can take action to prevent damage, protecting both the pump and the overall system.

Applications of Water Pump Controllers

Water pump controllers play a vital role in improving the efficiency and reliability of water systems across various industries. Whether for residential, agricultural, commercial, or industrial purposes, water pump controllers help optimize system performance.

· Residential Applications: Water pump controllers are commonly used in rainwater harvesting systems and garden irrigation systems, ensuring a reliable and consistent water supply while minimizing energy use.

· Agricultural Applications: Farmers rely on water pump controllers for irrigation systems, helping them conserve water, reduce energy consumption, and improve crop yields.

· Commercial Applications: In commercial buildings like hotels, offices, and shopping centers, water pump controllers manage water supply systems, including HVAC systems, to ensure consistent flow and pressure.

· Industrial Applications: In industries such as manufacturing, mining, and wastewater treatment, water pump controllers are essential for managing water flow and pressure, ensuring optimal performance in demanding environments.

Selecting the Right Water Pump Controller for Your Needs

When choosing a water pump controller for your system, it's essential to consider factors like compatibility, control method, user interface, and additional features.

Compatibility

Ensure that the controller is compatible with your pump's motor voltage, horsepower, and pump type (e.g., submersible or surface pumps). An incompatible controller could lead to reduced performance or damage to both the pump and the controller.

Control Method

Choose the appropriate control method for your needs. Constant pressure controllers are ideal for maintaining steady pressure, while variable speed controllers provide more dynamic control over pump performance.

User Interface

Look for a controller with an intuitive and user-friendly interface. The easier it is to adjust settings and monitor performance, the more effective the controller will be.

Additional Features

Consider controllers with built-in diagnostics, remote monitoring capabilities, and alarm notifications for issues such as low water levels or motor overload. These features can improve system maintenance and reduce downtime.

Conclusion

Water well pump control boxes are essential for optimizing water management systems in residential, agricultural, commercial, and industrial applications. By intelligently regulating pump speed, pressure, and flow, these controllers enhance system efficiency, save energy, and extend the life of your pump. Upgrading to a JNN Water pump controller can improve the reliability and performance of your water system, resulting in long-term savings and fewer operational disruptions.

Explore JNN's range of high-quality water pump controllers to find the right solution for your needs today.