Efficient water management is essential for industries, agriculture, and commercial buildings. Without proper control, water pumps may operate inefficiently, leading to excessive energy consumption, water wastage, and increased maintenance costs. Manually monitoring and adjusting pump operation is both labor-intensive and prone to human error. This is where an Automatic Water Pump Controller becomes invaluable, automating the process to ensure optimal water usage and system efficiency.

An automatic water pump control system is designed to regulate water pump operation without manual intervention, ensuring a consistent water supply while optimizing energy consumption. These controllers not only enhance system reliability but also contribute to long-term cost savings. This article will explore how these controllers work, the different types available, and how to choose the right one for your needs.

Table of Contents

What Is an Automatic Water Pump Controller?

How Does an Automatic Water Pump Controller Work?

Types of Automatic Water Pump Controllers

How to Choose the Right Automatic Water Pump Controller

Why Choose JNN Automatic Water Pump Controllers?

Conclusion

What Is an Automatic Water Pump Controller?

An Automatic Water Pump Controller is a device that automates the switching on and off of water pumps based on pre-set conditions such as water level, pressure, and flow rate. By intelligently managing pump operation, these controllers prevent water shortages, protect equipment, and reduce electricity usage. They are commonly used in industrial, commercial, and agricultural applications to ensure a seamless water supply.

Key Functions

Automatic Start and Stop: Activates the pump when water is needed and stops it once the demand is met, reducing unnecessary operation and extending the pump's lifespan.

Dry Run Protection: Prevents the pump from operating when there is no water, avoiding potential damage and overheating of the pump motor.

Pressure Regulation: Maintains consistent water pressure in the system, which is crucial for high-rise buildings, irrigation systems, and industrial applications.

Energy Efficiency: Reduces unnecessary pump operation, lowering electricity costs and minimizing environmental impact.

Remote Monitoring (for Smart Controllers): Some advanced controllers offer IoT-based remote monitoring capabilities, allowing users to track performance and troubleshoot issues from anywhere.

How Does an Automatic Water Pump Controller Work?

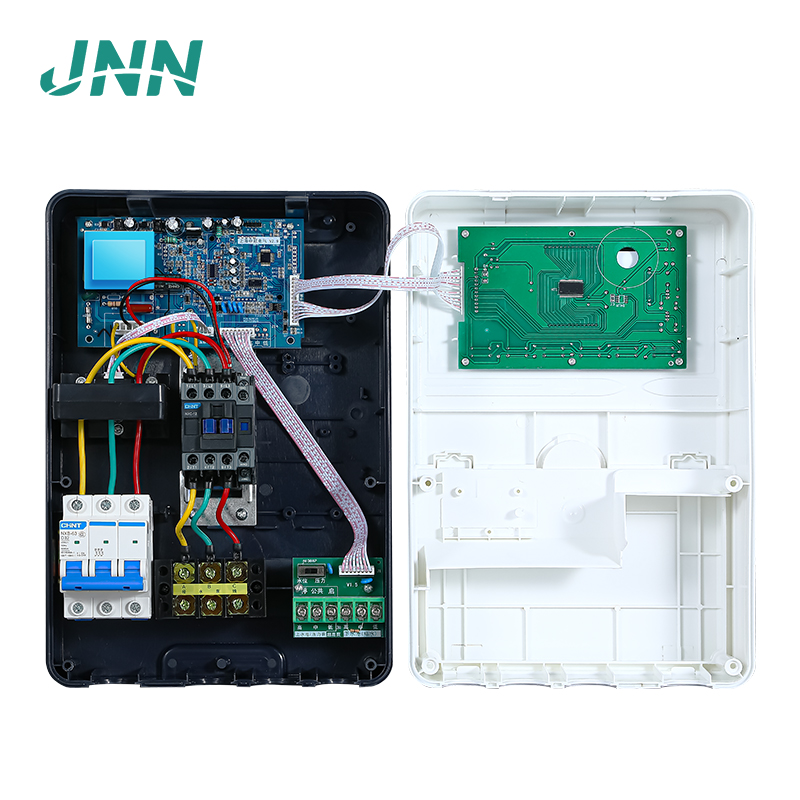

An Automatic Water Pump Control box operates through a combination of sensors, processing units, and actuators. The basic working mechanism involves four primary steps:

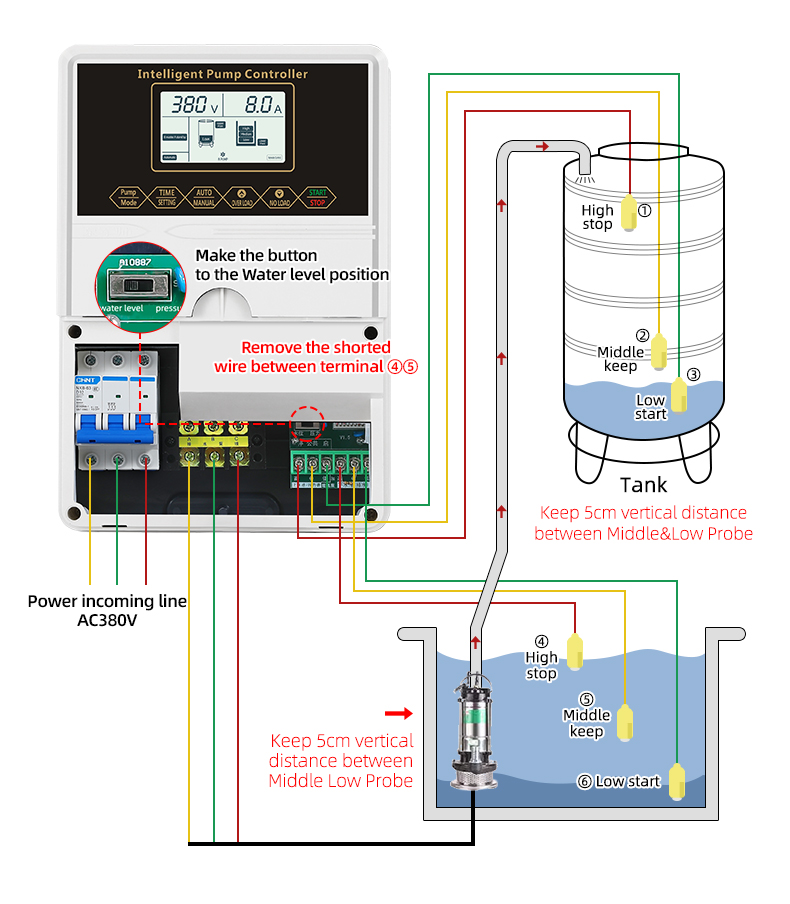

1. Sensing Water Level, Pressure, or Flow

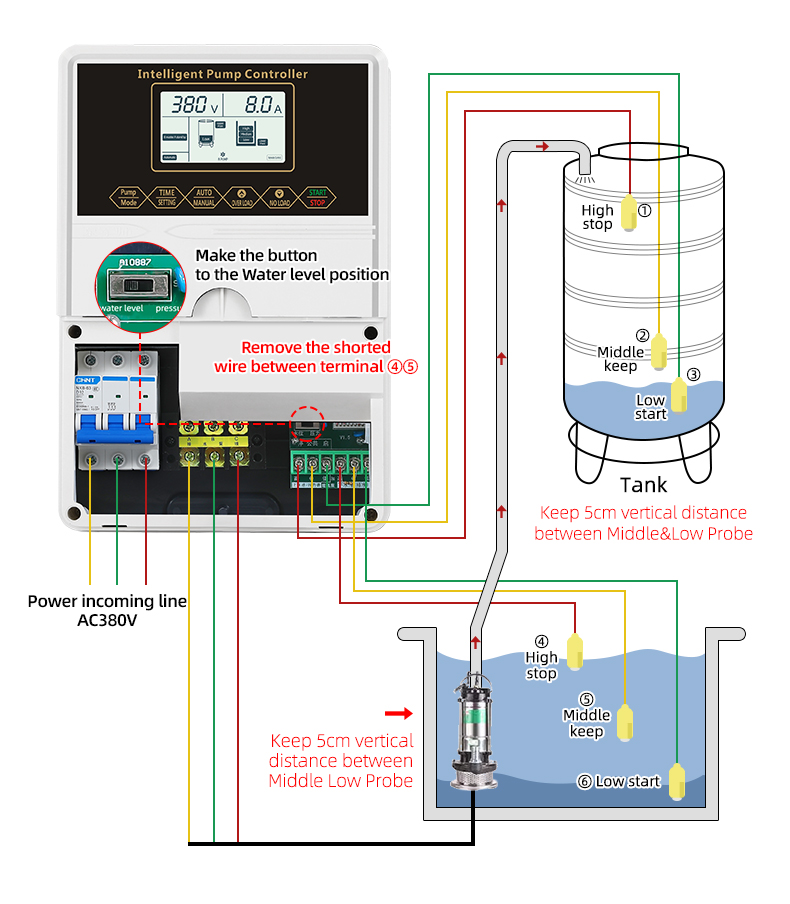

The system relies on sensors such as float switches, pressure transducers, or flow meters to detect changes in water conditions. These sensors provide real-time data to the controller, allowing it to react to changing conditions.

If the water level in a storage tank drops below a set point, the controller detects the low level and prepares to activate the pump.

If the pressure in the pipeline falls below the required threshold, the controller senses the change and ensures stable pressure by engaging the pump.

In more advanced systems, additional flow sensors monitor water usage, preventing unnecessary pump cycles and reducing wear and tear.

2. Processing Data and Making Decisions

A microcontroller or a relay-based system processes the sensor data and determines whether the pump should be turned on or off. The controller uses programmed algorithms to decide the appropriate action.

If the water level is low, the system signals the pump to start immediately, ensuring a continuous water supply.

If the water level reaches a full state, the system signals the pump to stop to prevent overflow and excessive energy consumption.

If abnormal conditions like dry running, pressure spikes, or electrical faults are detected, the controller stops the pump to prevent damage, alerting the user via alarms or remote notifications.

3. Activating the Pump

Once a decision is made, the controller triggers the relay to either start or stop the pump. The way this activation occurs depends on the type of controller being used.

In electronic controllers, solid-state relays ensure precise control and durability, reducing mechanical wear.

In traditional relay-based systems, an electromechanical switch controls the power supply to the pump, providing a more straightforward but less sophisticated solution.

Smart controllers integrate variable frequency drives (VFDs) for smoother pump operation and better energy management.

4. Providing Feedback and Safety Measures

Some controllers come with a display panel or indicators showing system status, such as pump activity, water levels, and power consumption. Advanced models may include alarms or remote notifications to alert users of faults, leaks, or maintenance needs.

IoT-enabled controllers provide real-time data logging, helping facility managers track performance trends and optimize water distribution.

Built-in fail-safes ensure that the system remains operational even under fluctuating conditions, reducing downtime and preventing costly repairs.

Types of Automatic Water Pump Controllers

Different applications require different types of controllers. Below are some common types:

1. Float Switch-Based Controllers

Uses a floating sensor in a water tank to detect water levels, making it one of the simplest and most reliable solutions.

When the water level drops, the float switch triggers the pump to refill the tank, and once the tank is full, it stops the pump.

Simple and cost-effective, commonly used for overhead water tanks, sumps, and groundwater wells where level monitoring is essential.

2. Pressure-Based Controllers

Uses pressure transducers to maintain consistent water pressure by turning the pump on and off as needed.

Suitable for booster pump systems in commercial buildings, high-rise apartments, and industrial water supply systems where stable pressure is required.

Prevents pipeline bursts and ensures optimal water distribution across multiple outlets.

3. Timer-Based Controllers

Allows the pump to operate on a pre-set schedule, ensuring regular water supply at specific intervals.

Useful for irrigation systems, water treatment plants, and municipal water supply networks where timed operation is necessary.

Can be integrated with other sensors to enhance automation and efficiency.

4. Smart IoT-Based Controllers

Supports WiFi or GSM-based remote monitoring and control, providing users with real-time data and remote access.

Ideal for industrial applications requiring precise automation and performance tracking.

Enables predictive maintenance, reducing downtime and improving overall system reliability.

Controller Type | Control Mechanism | Best Applications | Pros | Cons |

Float Switch-Based | Water level detection | Water tanks, wells | Simple, cost-effective | Limited control options |

Pressure-Based | Pressure transducers | Booster pumps, buildings | Ensures stable water pressure | Requires pressure calibration |

Timer-Based | Pre-set time schedules | Irrigation, water treatment | Automated scheduling | Lacks real-time monitoring |

Smart IoT-Based | Remote monitoring, sensors | Industrial automation | Real-time control, predictive maintenance | Higher initial cost, requires internet |

How to Choose the Right Automatic Water Pump Controller

When selecting a pump controller, consider the following factors:

Application Needs: Determine whether the system requires level-based, pressure-based, or smart automation to meet operational demands.

Pump Compatibility: Ensure the controller matches the pump's voltage, power rating, and operational requirements.

Safety Features: Look for dry run protection, overload protection, and surge protection to enhance pump longevity and reliability.

Ease of Installation and Maintenance: A user-friendly interface, clear wiring instructions, and minimal maintenance requirements can save time and labor costs.

Remote Control Capabilities: If remote monitoring and automation are essential, opt for an IoT-enabled model to improve operational efficiency.

Why Choose JNN Automatic Water Pump Controllers?

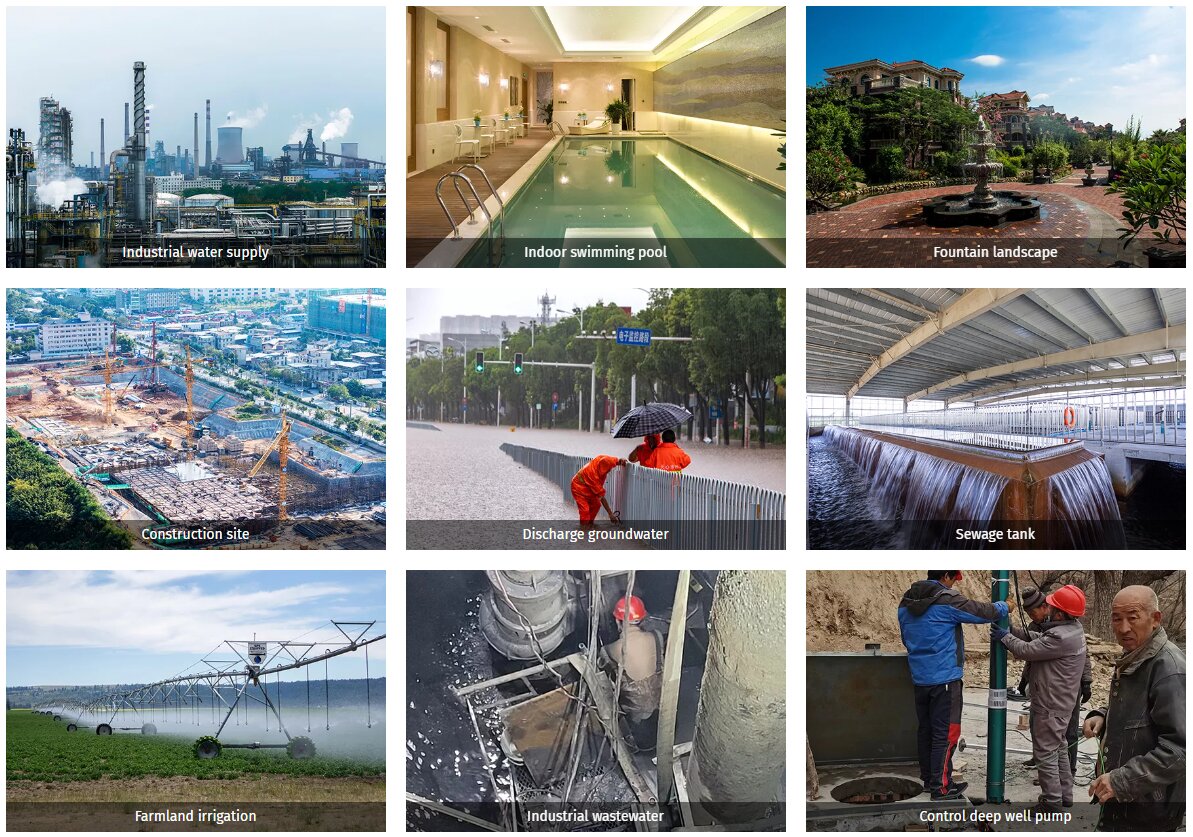

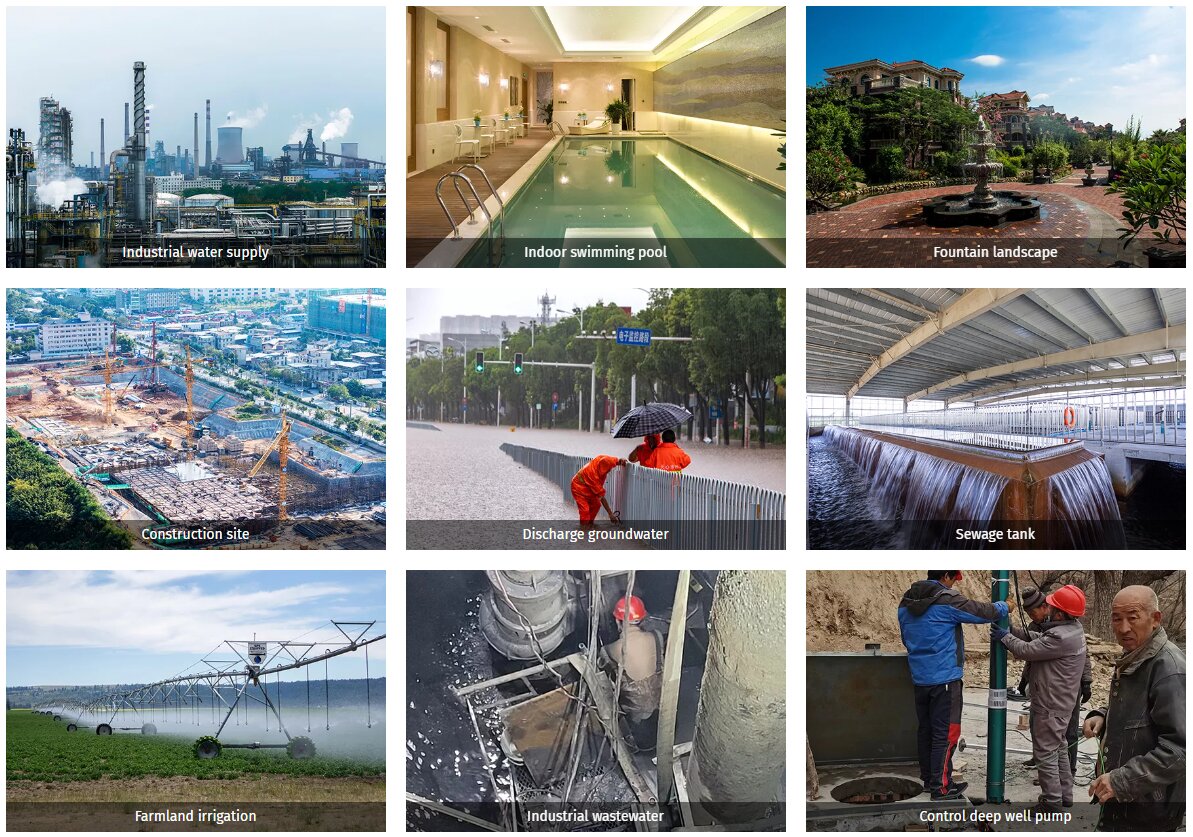

JNN provides high-quality Automatic Water well Pump Controllers designed for industrial, agricultural, and commercial water management applications. Our controllers offer:

Versatility: Compatible with various water pump types, including centrifugal, submersible, and booster pumps.

Smart Technology: Optional remote monitoring and advanced automation features for enhanced system control.

Energy Savings: Optimized pump operation reduces electricity costs while improving performance.

Built-in Protection: Overload and dry-run protection prevent pump failure and extend lifespan.

Custom Solutions: Tailored designs meet unique industry requirements, ensuring seamless integration.

Conclusion

An Automatic Water Pump Controller is a critical component in modern water management systems, ensuring efficiency, reliability, and cost savings. By understanding how these controllers work and selecting the right type for your needs, you can improve system performance while reducing maintenance and operational costs.

Explore JNN's range of Automatic Water Pump Controllers to find the ideal solution for your application. Contact us today for expert guidance and customized solutions!