The well pump control box is a key device to ensure the efficient and stable operation of the water well system. Choosing the right control box can not only improve the operating efficiency of the system, but also extend the service life of the equipment and reduce maintenance costs. When choosing a control box, you should consider factors such as price, power supply voltage, motor current and control type to ensure that the control box can meet your actual needs. By using the well pump control box correctly, you can effectively ensure the stability and reliability of your home water supply system. At the same time, correct installation and regular maintenance are also key measures to ensure the long-term stable operation of the control box. Whether it is a home or commercial occasion, the well pump control box is an indispensable and important part of the water system.

So, before we get to know the well pump control box in depth, what we need to know is, what is a well pump control box? What exactly does it do? Read on to learn more.

Functions of well pump control box

The well pump control box is basically the brain of the water system because it handles many tasks to keep the system running properly. It is not just a simple switch device, but an intelligent control system that can adjust the operation of the pump according to actual needs.

Monitoring and controlling water flow

One of the main functions of the pump control box is to monitor water flow and control the water pump to ensure that the water pump remains at the required operating level. By sensing changes in water flow and water pressure, the control box can dynamically adjust the operating status of the pump. For example, when water demand increases, it speeds up the pump, and when water demand decreases, it slows down the pump or shuts it down completely. This dynamic adjustment not only saves energy, but also extends the service life of the pump. In addition, the pump control box is able to adjust the start and stop time of the pump according to actual conditions, thereby avoiding the loss of the pump caused by frequent start and stop.

In some advanced control systems, the pump control box also has a remote monitoring function. Through the Internet of Things technology, users can view the operating status of the pump in real time through mobile phones or computers, and even remotely control the start and stop of the pump. This provides great convenience and security for those who need to be away from home for a long time.

Protecting the pump motor

The well pump control box is also responsible for protecting the pump motor from various electrical faults. For example, when the grid voltage is unstable, the control box can protect the pump motor through the built-in voltage regulator to avoid motor damage caused by excessive or low voltage. In addition, the control box also has short-circuit protection and overload protection functions. When the motor runs beyond its rated load, the control box will automatically cut off the power supply to protect the motor from damage.

The control box's protection function is not limited to electrical aspects. It can also monitor the operating temperature of the water pump to prevent the pump from being damaged by overheating. When the temperature of the pump exceeds the safe range, the control box will automatically shut down and restart when the temperature returns to normal. In addition, some control boxes also have a dry-burn prevention function. When the water level is too low, the control box will automatically shut down the pump to prevent the pump from burning out when running without water.

Multi-function control

Modern well pump control boxes have multiple functions and can be configured according to actual needs. For example, the control box can be configured to operate multiple pumps alternately to balance the service life of each pump. It can also adjust the running speed of the motor to avoid the problem of low water pressure. The control box can also sense the water level and automatically shut down the pump when the water level is too low to prevent the pump from drying out. In addition, the control box can also start the high-voltage motor to ensure sufficient water pressure during high demand.

In some large water systems, the control box can also realize the parallel operation of pumps to meet the needs of peak water use periods. This configuration not only increases the flexibility of the system, but also ensures that when a single pump fails, other pumps can continue to operate to ensure the continuity of water supply. In addition, the control box also has an automatic alarm function, which can promptly sound an alarm when the system fails, reminding users to check and maintain.

Considerations for choosing a well pump control box

When choosing a well pump control box, there are several important factors to consider:

Price

Price is an important factor when choosing a control box. Although many cheap control boxes may seem attractive, they often use inferior components, which may lead to frequent well pump repairs. Therefore, choosing a reliable control box, even if the price is slightly higher, will save more maintenance costs in the long run.

It should be noted that there are many brands and models of control boxes on the market, which vary greatly in price and performance. Consumers should consider their own needs and budgets when choosing, and do not blindly pursue low-priced products. At the same time, it is recommended to choose products with good after-sales service and brand reputation to ensure timely technical support and service during use.

Power supply voltage and motor current

When choosing a well pump control box, you must ensure that its voltage and current match the rated value of the pump. Usually, the voltage supplied to the water supply system will vary, so it is very important to determine the voltage and current of the pump before purchasing the control box. This ensures that the control box can operate normally and avoids motor damage caused by voltage mismatch.

In actual applications, the power requirements of the control box and the motor parameters of the pump must be precisely matched. For example, if the pump motor is three-phase and the control box is single-phase, then even if the other parameters of the control box meet the requirements, it will not work properly. In addition, the current capacity of the control box must also be greater than or equal to the rated current of the pump motor to prevent safety issues caused by overload.

Control type

There are many types of controls used to control pumps, each with its own advantages and disadvantages:

Float switch: rises and falls with the liquid level, simple and reliable, suitable for most household well water systems.

Sensor: measures the weight of water and is suitable for systems that require precise control of water levels.

Pressure switch: As the water level rises, the pressure in the bell increases, suitable for systems that need to maintain constant water pressure.

Choose the right control type according to your specific needs to ensure that the control box can meet your expectations and actual use requirements. Different control methods have different effects in applications, such as float switches are suitable for simpler systems, while sensors are suitable for scenarios that require fine control. When choosing the type of control, you also need to consider the complexity of the system and the difficulty of maintenance in order to choose the most suitable control method.

Specific operations of the well pump control box

The well pump control box can perform many specific operations to ensure the efficient operation of the water well system:

Alternately operate the pumps: balance the service life of each pump and avoid overuse of a single pump.

Change the speed of the motor: adjust the water pressure according to actual needs to avoid the problem of too low water pressure.

Protect the motor: prevent damage to the motor caused by incorrect voltage and water tank immersion.

Start the high-voltage motor: provide sufficient water pressure when demand is high.

Sense water flow and water level: automatically turn on or off the equipment to ensure stable operation of the system.

Control the chemical pump: start when needed to ensure the safety of water quality.

Start the well pump generator: provide backup power during power outages.

Display the running time: monitor the operating status of the pump in real time for easy maintenance and management.

The realization of these functions depends on the complex electronic circuits and software systems in the control box. Modern control boxes are usually equipped with microprocessors that can accurately control the operating parameters of the pump and record operating data. These data can help users understand the working status of the pump and promptly discover and solve potential problems.

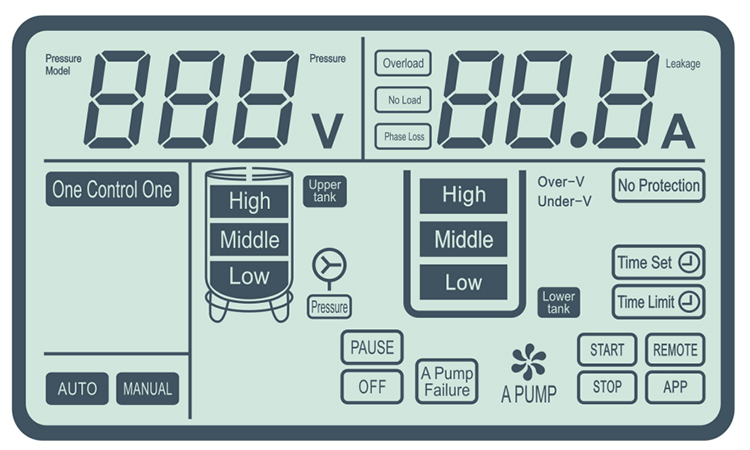

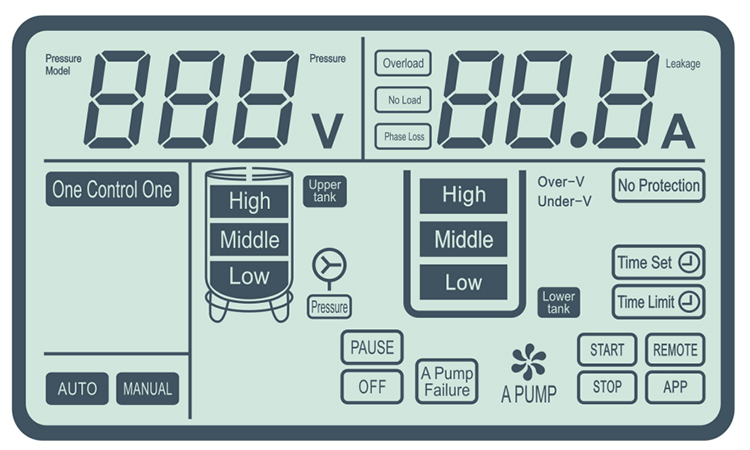

In actual operation, users can set various parameters through the interface of the control box, such as the start and stop time, the upper and lower limits of water pressure, etc. The advanced control box also supports remote control and data transmission functions, and users can monitor and adjust the operation status of the pump in real time through mobile phones or computers. This not only improves the convenience of operation, but also greatly enhances the safety and reliability of the system.

Installation and maintenance of well pump control box

In addition to choosing a suitable well pump control box, installation and maintenance are equally important. A properly installed control box can ensure the normal function of its functions, while regular maintenance can extend its service life.

Installation of well pump control box

When installing the well pump control box, ensure that its location is dry and well ventilated to avoid moisture and overheating. At the same time, it should be installed in accordance with the installation guide provided by the manufacturer to ensure that each connection point is firm and reliable. If you are not familiar with the installation process, it is recommended to ask a professional water pump technician to install it to ensure the safety and stability of the system.

During the installation process, special attention should be paid to the safety of electrical connections. All cables and wiring must comply with national safety standards and use suitable insulating materials. The housing of the control box should be firmly fixed to prevent loosening due to vibration or external force. At the same time, the control box should be well grounded to prevent leakage accidents.

Regular maintenance

The maintenance of the well pump control box mainly includes checking whether the electrical connection is firm, cleaning the dust and debris in the control box, and testing whether each function is operating normally. Every once in a while, you should also check whether the outer shell of the control box is damaged or aging. If you find any problems, you should replace or repair them in time. In addition, regular professional inspections are also necessary, especially in cases of frequent use or harsh environments.

Regular maintenance can not only extend the service life of the control box, but also improve the operating efficiency of the system. During the maintenance process, special attention should be paid to checking the circuit boards and components in the control box to ensure that there is no looseness or corrosion. If damaged components are found, they should be replaced in time. In addition, the protection functions of the control box, such as overload protection and short-circuit protection, should be tested regularly to ensure that it can work normally in an emergency.

Conclusion

With the advancement of science and technology, the functions and performance of the well pump control box are also constantly improving. In the future, intelligence and automation will become the development trend of the control box. Through the Internet of Things and big data technology, users will be able to achieve more sophisticated control and management, and further improve the operating efficiency and reliability of the water system. Therefore, choosing and using a well pump control box is not only a way to meet current water needs, but also an investment and guarantee for future development.