Efficient water management is essential in many industries and households, making water pump controllers an indispensable component of modern systems. By understanding how they function and identifying ways to optimize their performance, users can significantly enhance water conservation, reduce energy consumption, and extend the lifespan of their equipment.

This article will explore the basics of water pump controllers, their working mechanisms, and practical ways to improve their efficiency. Please continue reading. I believe it will help you understand water pump controllers.

What is a Water Pump Controller?

A water pump controller is an electronic device designed to manage the operation of water pumps automatically. These controllers ensure that pumps are activated and deactivated based on specific conditions, such as water levels, pressure, or flow requirements. They are widely used in agricultural irrigation, industrial processes, residential water systems, and municipal water supply networks.

Key Components of a Water Pump Controller

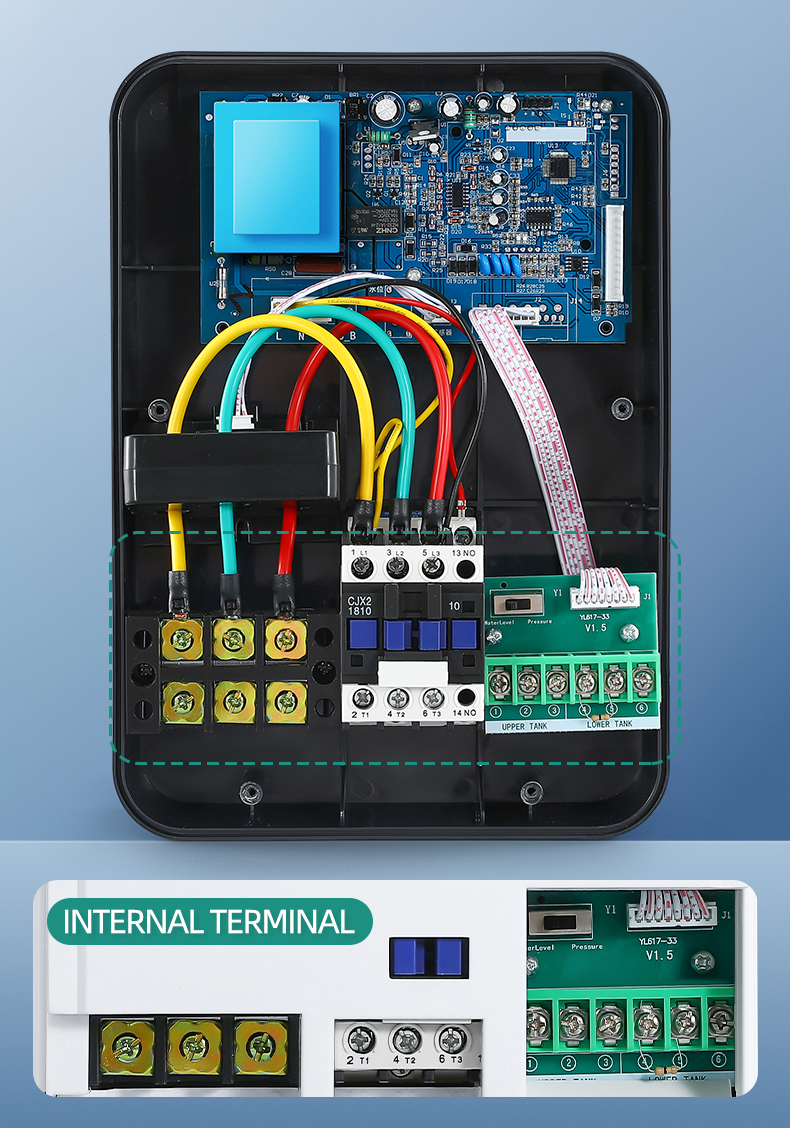

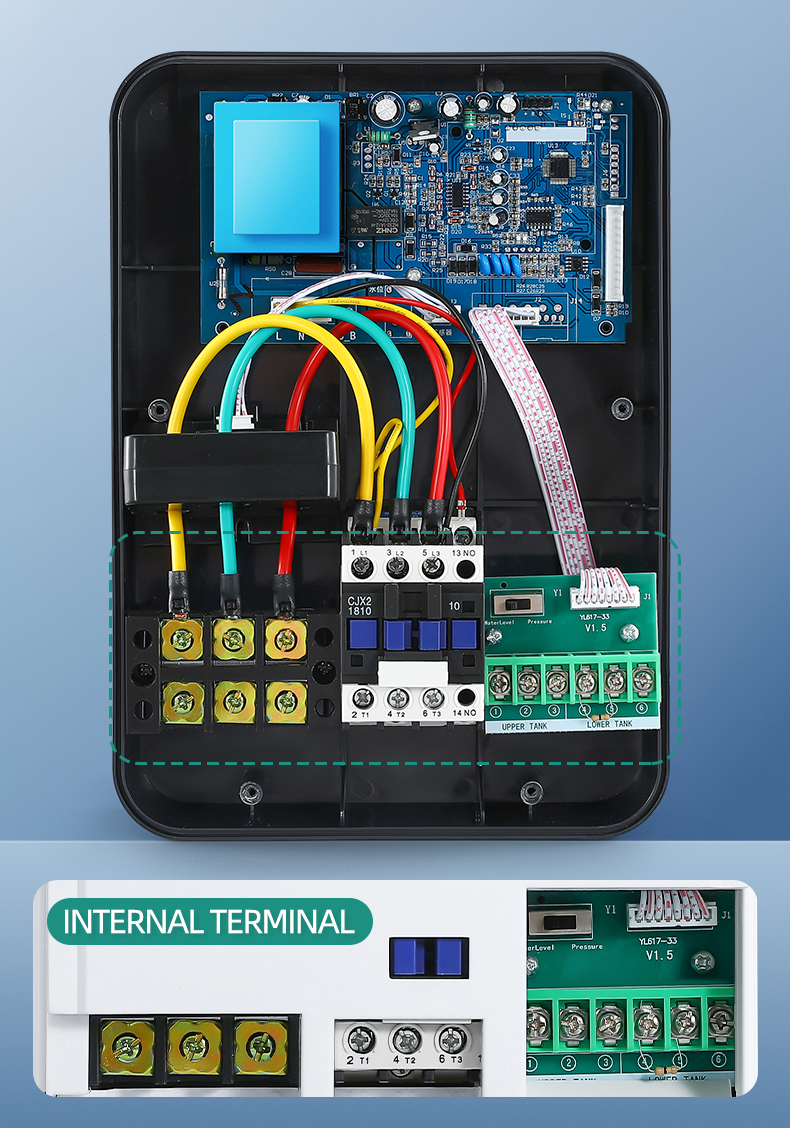

Sensors: Sensors detect parameters such as water levels in tanks, pressure in pipes, or flow rates. Common sensors include float switches, pressure sensors, and flow meters.

Control Unit: The control unit processes signals from sensors and decides when to start or stop the pump. It may include microcontrollers or programmable logic controllers (PLCs) for advanced functionality.

Relay/Switching Mechanism: This component acts as an intermediary, sending power to the pump motor when the controller signals it to operate.

Power Supply: Provides the necessary electrical power to the controller and, indirectly, the pump.

Types of Water Pump Controllers

Float Switch Controllers: Use float switches to detect water levels in tanks or reservoirs.

Pressure-Based Controllers: Rely on pressure sensors to regulate pump operation.

Smart Controllers: Incorporate IoT technology to enable remote monitoring and control via smartphones or computers.

Variable Frequency Drive (VFD) Controllers: Adjust motor speed based on demand, enhancing efficiency.

How Does a Pump Controller Work?

Water pump control boxes function by automating the operation of water pumps based on input from sensors. The process can be broken down into the following steps:

1. Sensor Input

Sensors continuously monitor relevant parameters, such as water levels in a storage tank or pressure within a pipeline. For instance:

A float switch rises or falls with the water level, sending an electrical signal to the controller.

A pressure sensor detects changes in pipe pressure, signaling the need for more or less pumping action.

2. Signal Processing

The controller's control unit receives signals from the sensors and evaluates them against pre-set thresholds. For example:

If the water level in a tank drops below a certain point, the controller signals the pump to start filling the tank.

If the pipeline pressure exceeds a defined limit, the controller stops the pump to prevent overpressure.

3. Relay Activation

Based on the processed signals, the controller activates or deactivates the relay, which connects or disconnects the pump motor from the power supply. This ensures the pump operates only when needed, preventing unnecessary wear and tear.

4. Continuous Monitoring and Adjustment

Advanced controllers, such as those using VFD technology, continuously adjust pump speed and operation to match real-time demand, optimizing energy consumption and performance.

Methods to Improve the Efficiency of Water Pump Controllers

Enhancing the efficiency of water well pump control boxes involves optimizing energy use, ensuring reliable operation, and reducing maintenance requirements. Below are practical strategies to achieve these goals:

1. Use Energy-Efficient Pumps

Pairing the controller with an energy-efficient pump significantly reduces power consumption. Look for pumps with high-efficiency motors and features like variable-speed operation.

2. Install Variable Frequency Drives (VFDs)

VFD controllers adjust the pump's motor speed based on real-time demand. This not only saves energy but also reduces mechanical stress on the pump, extending its lifespan.

3. Regular Maintenance of Sensors and Controllers

Faulty sensors or controllers can lead to inefficient operation or system failure. Regularly inspect and clean sensors, check for loose connections, and update controller firmware if applicable.

4. Optimize System Design

Ensure the entire water system, including pipelines and tanks, is designed for minimal resistance and optimal flow. This reduces the workload on pumps and enhances overall efficiency.

5. Utilize Smart Controllers

Smart controllers with IoT capabilities allow remote monitoring and control. Users can adjust settings, monitor performance, and receive alerts for potential issues, enabling proactive maintenance.

6. Conduct Energy Audits

Periodically assess the energy consumption of your water pumping system. Identify inefficiencies and take corrective measures, such as resizing pumps or updating old equipment.

7. Insulate Pipelines and Tanks

Minimizing heat loss in pipelines and storage tanks reduces the energy required to maintain desired water temperatures, especially in hot water applications.

8. Implement Leakage Detection Systems

Leaks in the water system can cause pumps to work harder to maintain pressure. Regularly inspect for leaks and address them promptly to improve efficiency.

9. Optimize Pump Scheduling

For applications like agricultural irrigation, schedule pump operations during off-peak hours to reduce energy costs and balance system demand.

Conclusion

Water well pump controllers play a vital role in ensuring the efficient and reliable operation of water management systems. By understanding how these devices work and adopting methods to optimize their performance, users can achieve significant savings in energy and maintenance costs while enhancing system reliability. Whether through the integration of smart technologies, the use of VFDs, or routine maintenance, improving the efficiency of water pump controllers is an investment that pays long-term dividends for both residential and industrial applications.